Custom metal brackets and housings might seem like minor details in an LED lighting system, but they often make the difference between a basic setup and a high-performance, long-lasting solution.

Whether you’re in industrial manufacturing, architectural design, or urban infrastructure, you need your LED lights to perform reliably, look clean, and last as long as possible.

So, can custom brackets and housings actually improve LED efficiency and durability? Yes—they absolutely can.

These components manage heat, protect sensitive electronics, ensure stable installation, and allow for more precise lighting control. In short, they’re essential for maximizing performance and ROI.

In this article, we’ll explore why more businesses are turning to custom metal solutions, how different materials impact LED longevity, and which industries benefit most.

-

Table Of Contents

-

1. Can Custom Metal Brackets and Housings Really Make Your LED Lighting More Efficient?

-

2. What Are Custom Metal Brackets and Housings?

-

3. Why Heat Dissipation Should Be Your First Concern?

-

4. What Materials Work Best for LED Brackets and Housings?

-

5. How Do Custom Components Affect LED Lifespan?

-

6. How Does Customization Improve Light Distribution and Efficiency?

-

7. Real-World Applications: Who Benefits Most?

-

8. Are There Any Case Studies That Prove the Value?

-

9. What Should You Ask Before Ordering Custom Brackets or Housings?

-

10. Summary

What Are Custom Metal Brackets and Housings?

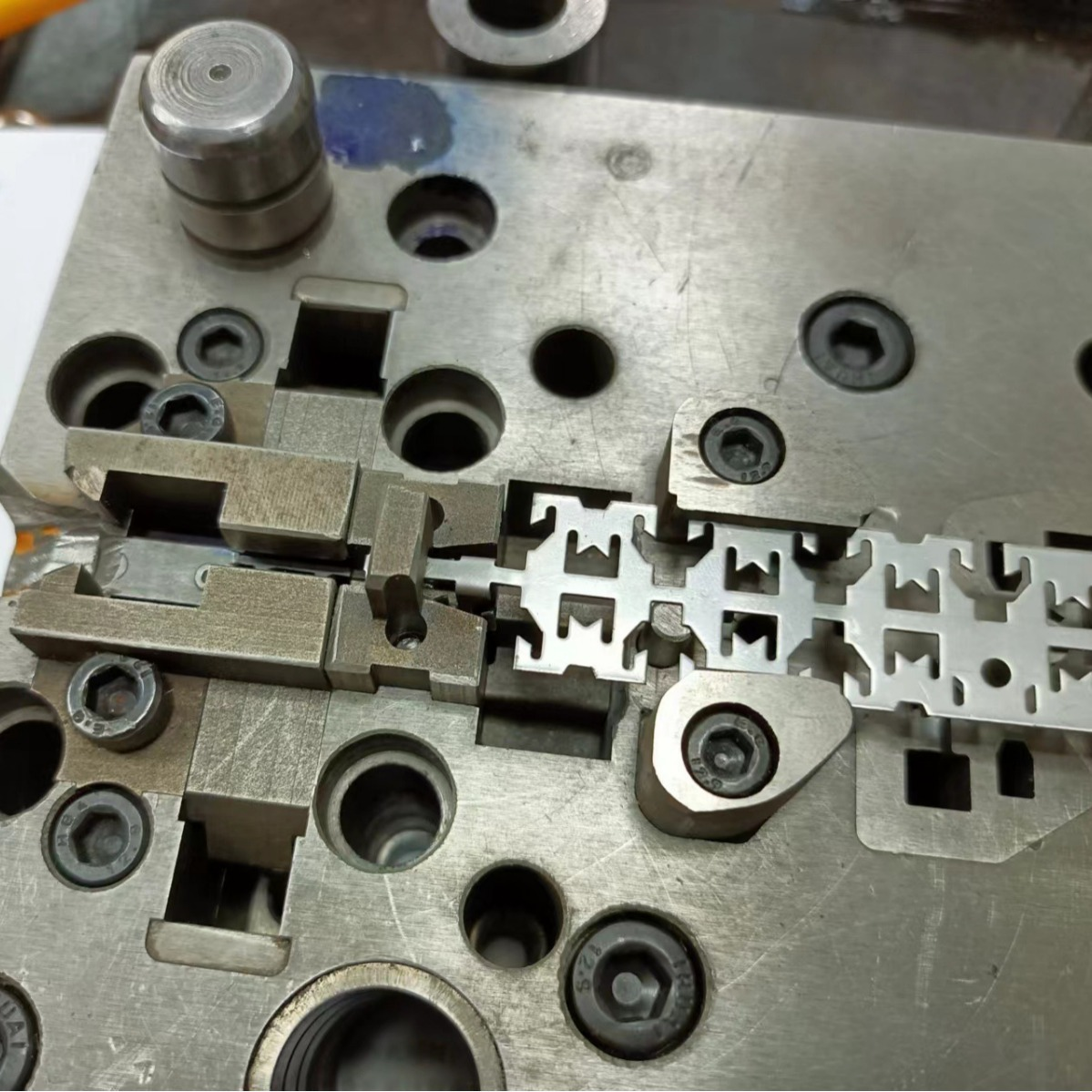

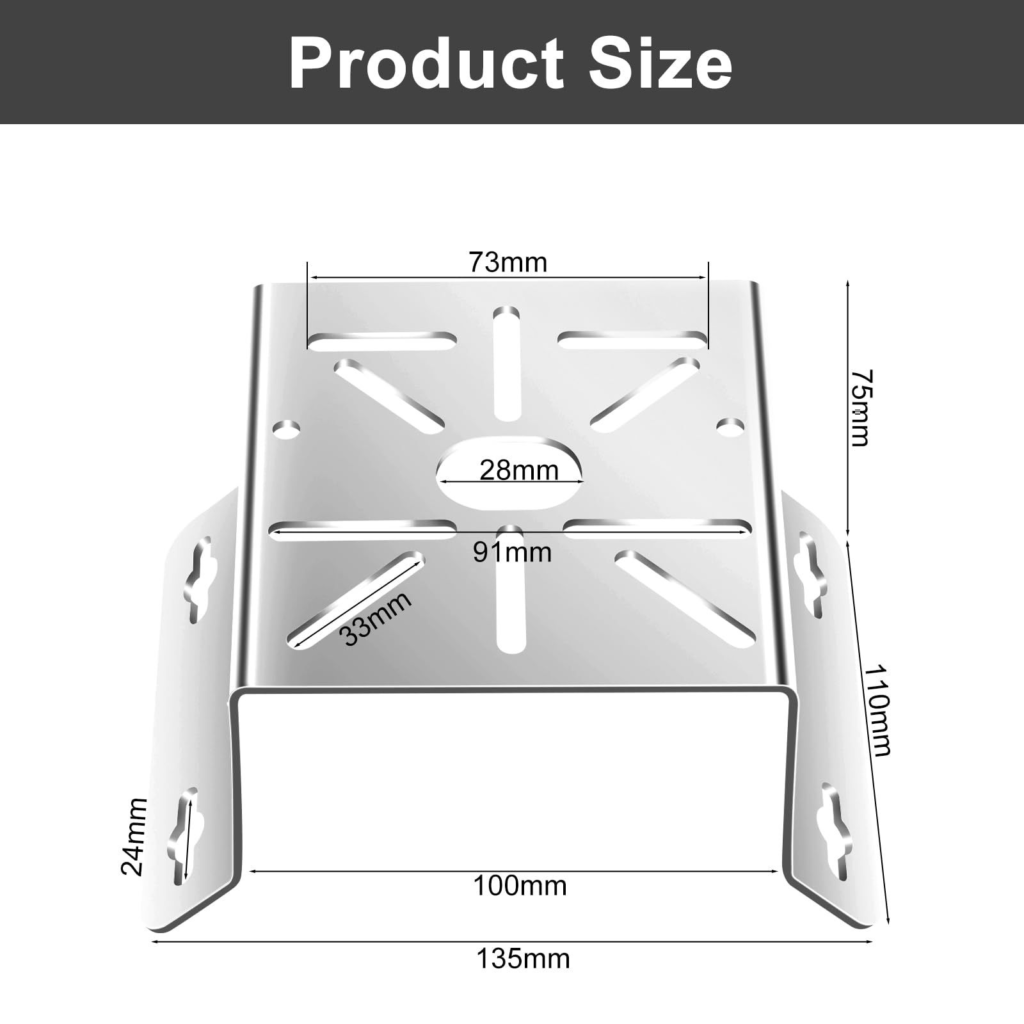

Custom metal brackets and housings are tailored structural supports and enclosures designed to enhance LED performance in specific applications.

Unlike generic fixtures, custom versions are built to meet your project’s exact requirements—whether you’re mounting lights on a factory ceiling or illuminating an architectural facade.

Key Benefits of Custom Brackets:

• Precise Positioning: Angle and aim light exactly where needed

• Enhanced Durability: Withstand vibration, wind, or physical impact

• Efficient Installation: Compatible with complex environments or retrofit projects

• Design Flexibility: Accommodate unique layouts or decorative finishes

Common Types:

• Fixed brackets for permanent setups

• Adjustable or swivel brackets for flexible angling

• Flush-mount brackets for discreet, aesthetic integration

• Suspended brackets for hanging fixtures in high-ceiling areas

Every project is different—so using the right bracket type ensures your LEDs are stable, effective, and easy to maintain.

Why Heat Dissipation Should Be Your First Concern?

LEDs are more efficient than incandescent bulbs, but they still generate heat.

Without proper heat management, that excess heat reduces lifespan, dims brightness, and increases the risk of failure.

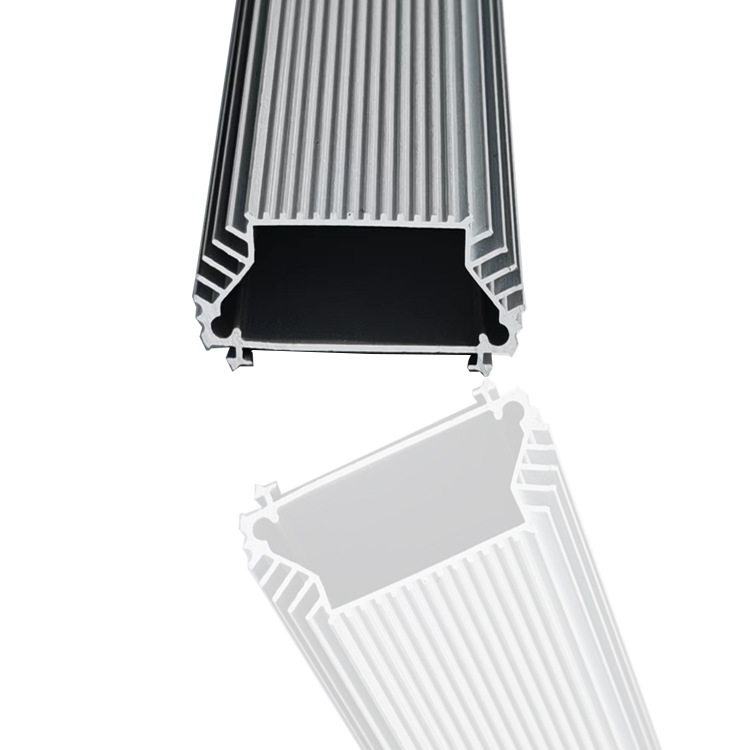

That’s where well-designed housings and brackets come in.

How Custom Metal Housings Help:

• Aluminum housings act as heat sinks, dispersing thermal energy quickly

• Vented designs improve airflow and cooling

• Powder-coated surfaces reflect heat and protect finishes

• Copper-enhanced housings offer premium heat performance for high-end systems

Especially in high-wattage, high-lumen, or outdoor applications, managing heat isn’t optional—it’s critical.

What Materials Work Best for LED Brackets and Housings?

The right material depends on your environment, budget, and performance needs. Here’s a breakdown:

Material | Benefits | Best Use Cases |

Aluminum | Lightweight, corrosion-resistant, great heat dissipation | Most general-purpose LED applications |

Stainless Steel | High strength, weather-proof, scratch resistant | Outdoor, marine, or industrial setups |

Copper | Best thermal conductivity | High-end lighting needing top-tier cooling |

Powder-Coated Steel | Affordable and durable | Signage, indoor commercial fixtures |

If weight and heat matter most, aluminum is your best bet.

If strength and longevity matter more, go with stainless steel.

How Do Custom Components Affect LED Lifespan?

Custom metal brackets and housings don’t just improve installation—they extend how long your LED system works.

Protection from:

• Physical damage (e.g., warehouse forklifts, falling tools)

• Environmental stress (e.g., dust, humidity, salt air)

• UV exposure and extreme temperature swings

• Water ingress, especially in IP-rated outdoor systems

By reducing these stressors, your system will last longer, require fewer replacements, and perform more consistently.

How Does Customization Improve Light Distribution and Efficiency?

If your lighting is poorly aimed or installed with generic mounts, you’re wasting energy and underperforming.

Custom brackets allow for:

• Targeted light output: Aim exactly where needed, avoiding dark spots or glare

• Reduced energy consumption: Less over-lighting, more control

• Tighter integration: Blend fixtures into architecture or branding elements

This not only enhances visual quality but also saves on operational costs.

Real-World Applications: Who Benefits Most?

Customization is especially valuable when you’re dealing with high expectations, demanding environments, or strict aesthetic goals.

Here are just a few examples:

Manufacturing & Warehouses

• Challenge: High ceilings, vibration, dust

• Solution: Sturdy suspended brackets with aluminum housings for heat and impact resistance

Architectural Lighting

• Challenge: Aesthetic integration, hidden wiring

• Solution: Flush-mounted brackets and decorative stainless housings

Stadiums & Arenas

• Challenge: Weather exposure, height, heavy-duty use

• Solution: Corrosion-resistant stainless steel with adjustable angles for floodlight control

Public Infrastructure

• Challenge: Continuous exposure to elements, vandalism risk

• Solution: Tamper-proof, powder-coated steel enclosures

Are There Any Case Studies That Prove the Value?

Yes—here are three practical examples:

Case 1: Industrial Warehouse Efficiency

A logistics company upgraded to high-lumen LED fixtures but had difficulty with angled installation.

Custom aluminum brackets allowed fast mounting on uneven beams and improved light spread, reducing energy costs by 20%.

Case 2: Hotel Architectural Integration

A luxury hotel wanted LED lighting to blend into its minimalist lobby.

Custom flush-mount stainless housings allowed seamless wall integration, maintaining aesthetic appeal while protecting from cleaning chemicals.

Case 3: Stadium Weather Resistance

A sports complex needed powerful outdoor lighting that wouldn’t fail in rain or wind.

Stainless brackets with anti-corrosion coating kept floodlights stable through multiple seasons of extreme weather.

What Should You Ask Before Ordering Custom Brackets or Housings?

Before placing an order, here are four questions you should always ask your supplier:

1. What is the environmental exposure for my lighting setup? (Indoor, outdoor, coastal, industrial?)

2. What’s the required heat dissipation level? (High-lumen lights need better cooling.)

3. Do I need adjustability or fixed angles? (Depends on the lighting goal.)

4. Are aesthetics or branding a factor? (Will the housing be visible to customers?)

Answering these early helps avoid costly redesigns and ensures the product truly fits your project needs.

Conclusion

In the fast-evolving world of LED lighting, performance and reliability matter more than ever.

Custom metal brackets and housings provide the structural integrity, thermal efficiency, and design flexibility that off-the-shelf components simply can’t match.

Whether you’re building a large-scale industrial system or refining a high-end architectural project, these tailored solutions help you achieve better results with fewer compromises.

By investing in customization, you’re not just enhancing your lighting—you’re future-proofing it.