Have you ever wondered how power flows so efficiently in today’s advanced electrical setups, from homes to industries?

The answer lies in busbars—innovative components designed for efficient, safe, and scalable power distribution.

Despite their significance, they often remain behind the scenes in discussions about electrical infrastructure.

So, why are busbars crucial?

Simply put, they streamline electricity transfer, reduce energy losses, and support high-demand applications.

Their versatility extends across residential, industrial, and renewable energy systems, making them a backbone of modern power distribution.

This article will dive into everything you need to know about busbars—their definition, purpose, advantages, and the innovations propelling them into the future.

Let’s explore how they compare to traditional wiring systems and why they are indispensable for efficient energy management.

-

Table Of Contents

-

1. Why Are Busbars Crucial for Modern Electrical Systems?

-

2. What Is a Busbar?

-

3. Types of Busbars

-

4. Advantages of Using Busbars

-

5. The Purpose of a Busbar

-

6. How to Choose the Right Busbar?

-

7. Busbars vs. Traditional Wiring

-

8. Innovations in Busbar Technology

-

9. A Quick Guide to Installation and Maintenance

-

10. Tackling a Common Concern: Are Busbars Expensive?

-

11. How to Ensure the Longevity of Your Busbar System

-

12. Summary

What Is a Busbar?

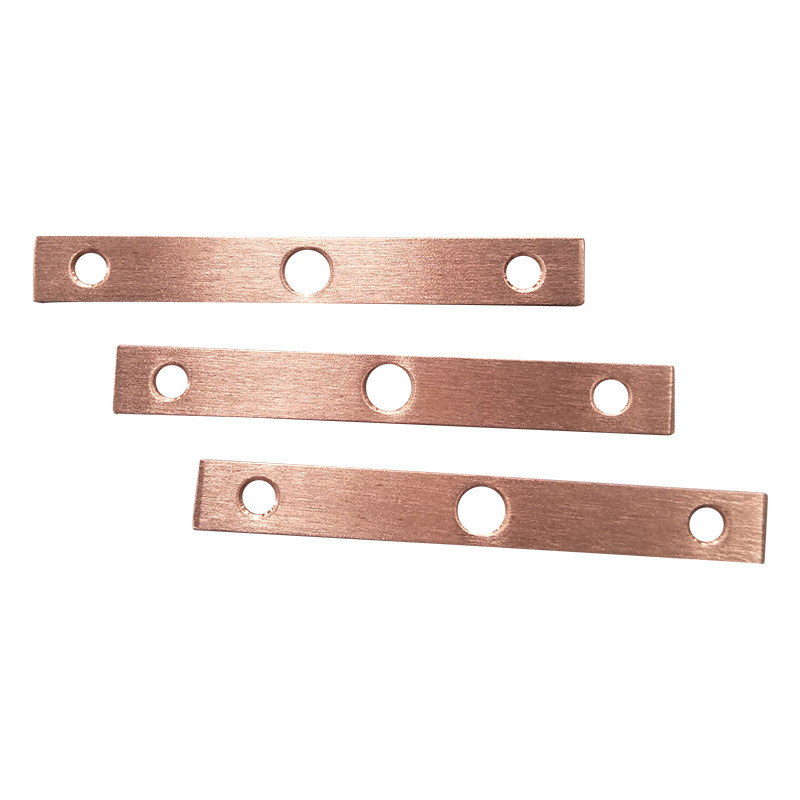

A busbar is a conductive metallic strip or bar that efficiently transfers electricity between power sources and electrical components.

Acting as a central hub in electrical systems, it consolidates multiple connections, simplifying complex setups while maintaining reliability.

Materials and Construction

Busbars are typically made from materials with high electrical conductivity to ensure optimal performance:

• Copper: Known for excellent conductivity and corrosion resistance, copper busbars are ideal for energy-intensive applications.

• Aluminum: A lighter and cost-effective alternative, aluminum is suited for projects prioritizing affordability or reduced weight.

Key Features of Busbars

• High Conductivity: Minimal resistance ensures efficient energy transfer.

• Durability: Understands mechanical stress, high temperatures, and environmental challenges.

• Modular Design: Enables space-saving installations and easy system upgrades.

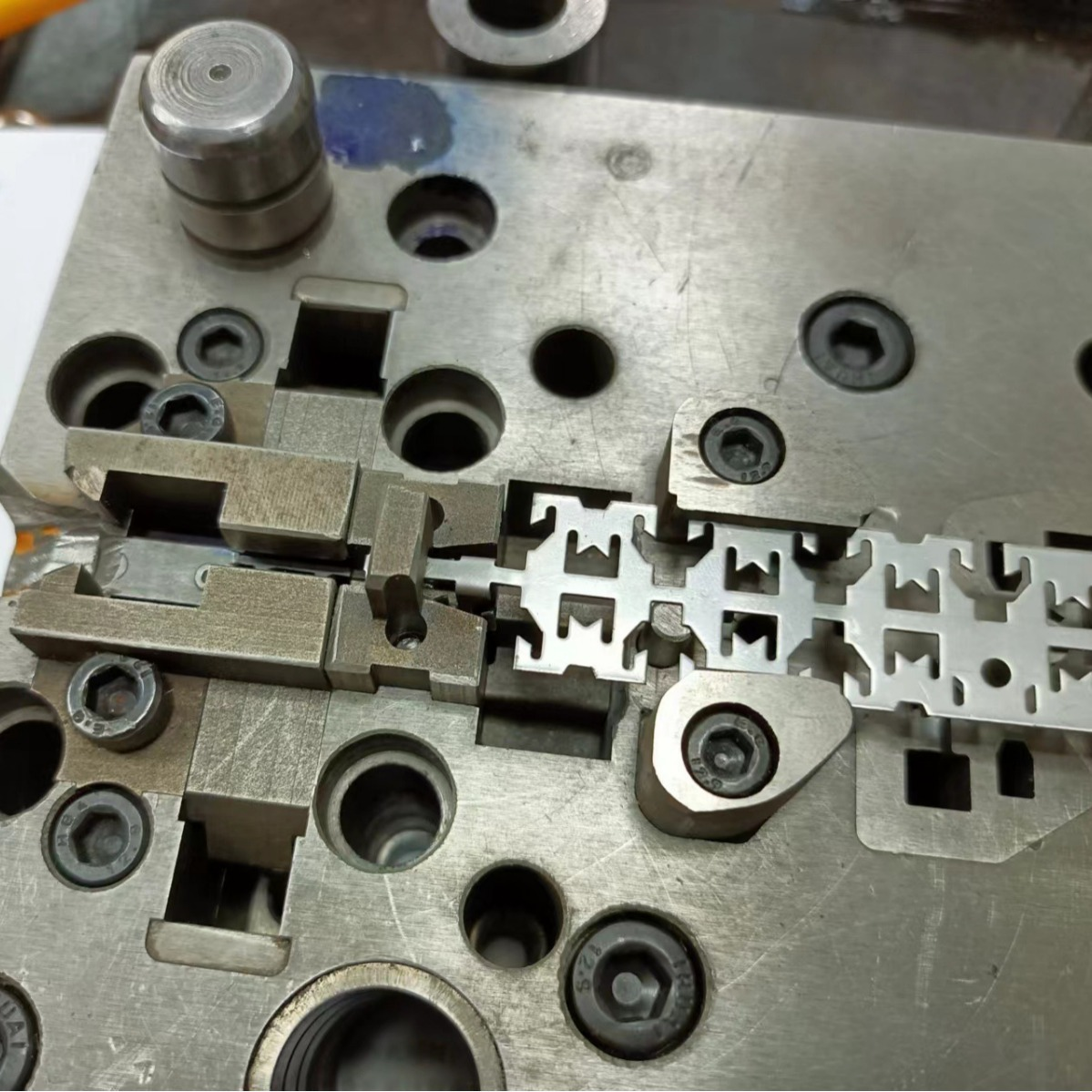

At Partzcore’s metal stamping services, we understand the critical role of precision in busbar manufacturing.

Types of Busbars

Single Busbar System

A cost-effective option for smaller applications with straightforward needs.

Double Busbar System

Ideal for large-scale installations requiring redundancy and flexibility, ensuring uninterrupted power supply.

Main and Transfer Busbar System

This setup allows seamless switching during maintenance and is commonly used in critical facilities like hospitals.

Insulated Busbars

These busbars enhance safety with protective coatings and are suitable for environments with high risks of accidental contact.

Advantages of Using Busbars

Durability and Reliability

Busbars are engineered for long-term use and resist wear, tear, and harsh environmental conditions.

Flexible Installation

Their modular nature allows for easy setup, expansion, and reconfiguration.

Enhanced Safety

Modern busbars significantly reduce risks like short circuits and overheating, especially when insulated.

Aesthetic Appeal

Compared to traditional wiring, busbars provide a cleaner, more organized look, which is critical in visible areas.

The Purpose of a Busbar

Efficient Power Distribution

Busbars are central conduits, reducing wiring complexity and ensuring smooth power flow across systems.

Minimizing Power Losses

Low resistance in busbars translates to minimal energy loss, lowering operational costs and supporting sustainability goals.

Handling High Current Loads

Designed for heavy-duty applications, busbars are indispensable in environments requiring high power, such as data centers and industrial facilities.

Renewable energy systems, connecting solar panels and wind turbines

How to Choose the Right Busbar?

When selecting a busbar, consider these factors to ensure it meets your specific needs:

1. Material Selection

Choose between copper and aluminum based on budget, conductivity, and environmental conditions. Copper is preferred for high-performance systems, while aluminum is suitable for cost-sensitive projects.

2. Capacity Requirements

Ensure the busbar can handle the intended electrical load to prevent overheating or failures.

3. Safety Measures

Opt for insulated busbars or protective coatings to mitigate risks in high-risk environments.

4. Space Considerations

Compact busbar designs are available for installations with limited space.

By focusing on these aspects, users can select busbars that deliver efficiency, safety, and long-term reliability.

Busbars vs. Traditional Wiring

Efficiency

Busbars offer superior energy efficiency due to lower resistance and better current distribution.

Maintenance

Unlike traditional wires, busbars require minimal maintenance and have a longer lifespan, making them cost-effective in the long run.

Safety

Busbars provide enhanced safety, with insulation and robust designs reducing risks of electrical faults.

Innovations in Busbar Technology

Smart Busbars

Equipped with sensors, these systems provide real-time data on power flow and system health, improving load management.

IoT and AI Integration

Future busbars will use AI for predictive maintenance and load optimization, enhancing overall system efficiency.

Compact Design Solutions

Innovations in engineering enable smaller, space-saving busbar designs for urban and industrial settings.

A Quick Guide to Installation and Maintenance

1. Professional Installation

Engage certified technicians to ensure safe and efficient setup.

2. Routine Inspections

Regularly check for wear, corrosion, or loose connections to prevent system failures.

3. Testing

Conduct periodic load and resistance tests to ensure the busbar remains efficient and reliable.

Tackling a Common Concern: Are Busbars Expensive?

One frequent misconception is that busbars are prohibitively costly.

While their upfront costs, especially for copper variants, may seem high, the long-term benefits outweigh these expenses.

Here’s why:

• Reduced Energy Loss: Lower resistance translates to lower operational costs.

• Minimal Maintenance: Durability means fewer repairs or replacements.

• Longevity: A well-maintained busbar system can last decades, making it a smart investment.

How to Ensure the Longevity of Your Busbar System

Maximizing your busbar system’s lifespan requires proper installation, regular maintenance, and environmental considerations.

Start by engaging certified technicians for installation to ensure compliance with industry standards and avoid operational risks.

Schedule routine inspections to check for signs of wear, corrosion, or overheating, addressing potential issues before they escalate.

Consider the operating environment—extreme temperatures or high humidity levels can accelerate degradation.

Using protective coatings or insulated busbars can mitigate these risks.

Additionally, electrical loads should be monitored to prevent overloading, which can lead to inefficiency or damage.

These practices extend the busbar’s lifespan and enhance system performance and safety.

Our metal fabrication expertise ensures we understand the precision required in busbar manufacturing.

Conclusion

Busbars are a cornerstone of modern electrical systems, offering unmatched efficiency, reliability, and safety.

Their versatility spans residential, industrial, and renewable energy applications, simplifying power distribution and supporting sustainability.

With innovations like innovative systems and AI integration, busbars are meeting today’s demands and paving the way for the future of energy management.

Whether you’re an engineer, facility manager, or homeowner, understanding the benefits of busbars empowers you to make informed decisions that enhance the performance and reliability of your electrical systems.