In the world of AI robotics, speed, precision, and adaptability aren’t optional—they’re expected.

Whether you’re a robotics manufacturer, a component buyer, or an automation engineer, you’re likely asking: how do these smart machines achieve such incredible performance?

The answer lies in their core—the CNC-machined parts that make their brains work and bodies move.

So, what CNC parts do AI robots truly rely on?

The essential ones include structural frames, motion gears, modular tooling, end effectors, and motor housings.

These high-precision components ensure that robots perform consistently in complex environments, from surgical theaters to automotive assembly lines.

In this article, we’ll delve into the most important CNC components used in AI robots, explain how they’re made, and explore why CNC machining is the gold standard in intelligent automation.

-

Table Of Contents

-

1. What CNC Parts Do AI Robots Rely On?

-

2. Why CNC Machining Is Indispensable in AI Robotics?

-

3. Must-Have CNC Parts in AI Robots and What They Actually Do?

-

4. How CNC Machines Shape the Future of Robotics?

-

5. CNC vs. 3D Printing in Robotic Parts

-

6. What If You’re Sourcing CNC Robot Parts for the First Time?

-

7. Summary

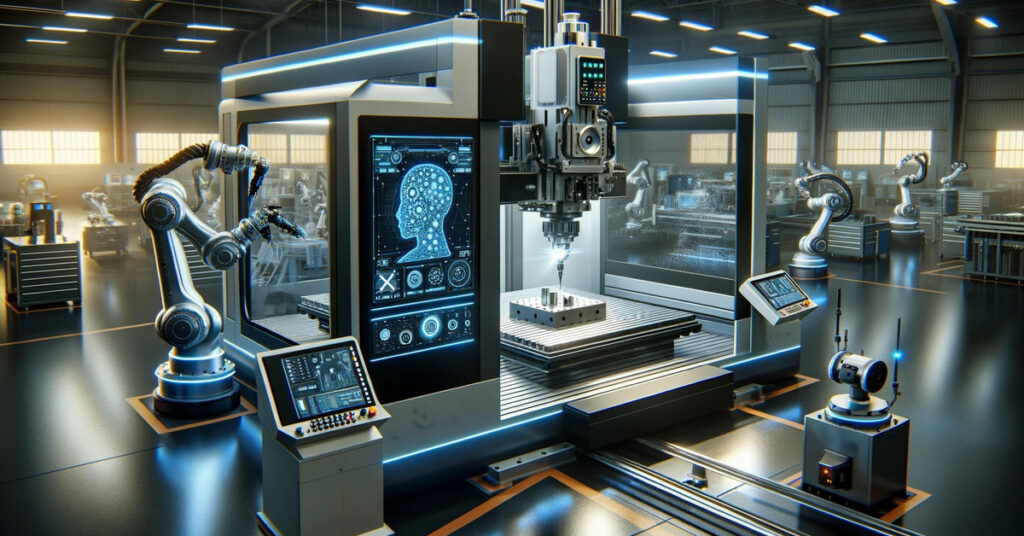

Why CNC Machining Is Indispensable in AI Robotics?

CNC (Computer Numerical Control) machining has become the go-to solution for producing robotic components, and with good reason. It offers:

Exceptional precision – Critical for robotic systems requiring micron-level accuracy.

Unmatched durability – CNC parts endure constant movement, weight, and mechanical stress.

Custom complexity – Supports intricate geometries needed for robotics.

Scalability – Ideal for mass-producing consistent, reliable parts.

From robotic arms to tiny precision gears, CNC machining ensures every piece fits perfectly—and performs flawlessly—in the most demanding applications.

Must-Have CNC Parts in AI Robots and What They Actually Do?

CNC machining is essential for crafting high-precision parts that power AI robots.

The most common CNC-manufactured components include structural frames, gears, end effectors, modular tooling, motor components, and assembly fixtures.

These parts ensure durability, accuracy, and flexibility in robotic systems. Below, we’ll explore these parts in detail.

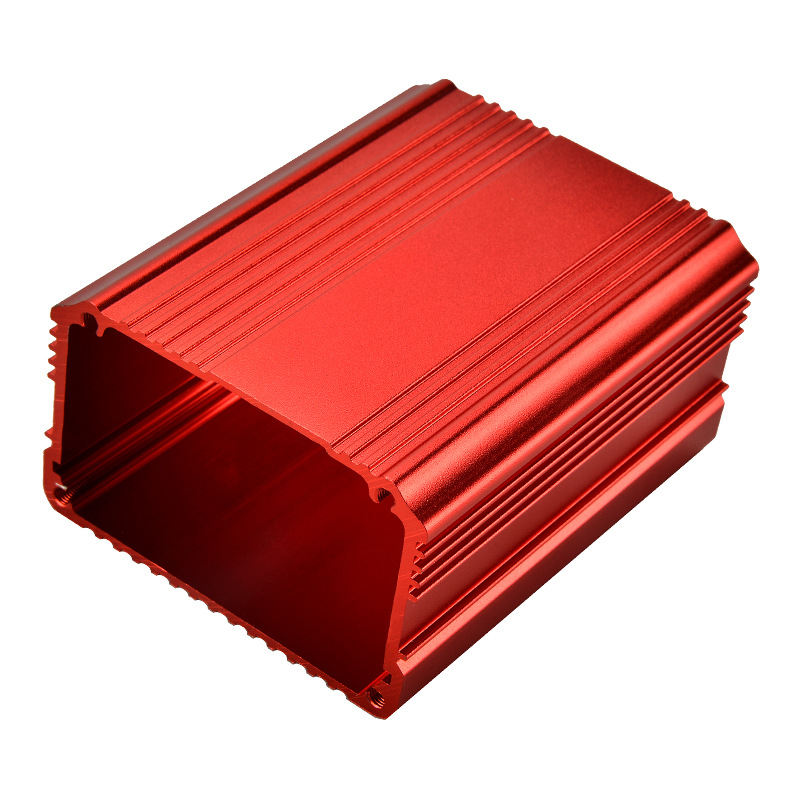

1. Structural Frames and Chassis

These are the skeletons of AI robots, defining shape, movement capability, and durability.

CNC machining produces frames from aluminum, carbon fiber composites, or titanium with ultra-tight tolerances.

Why it matters:

a. Provides stability and balance to internal components

b. Reduces vibration for more accurate movement

c. Lightweight designs improve energy efficiency

2. Gears and Bearings for Motion Control

AI robots often switch between different tools to perform tasks.

CNC machining allows for interchangeable end effectors, tool holders, and cutting heads.

a. Gears – Transfer rotational force between motors and joints.

b. Bearings – Reduce friction and enable smooth motion.

c. Worm Gears & Helical Gears – Used in robotic arms for accurate movement.

3. Modular Tooling for Custom Functions

Modularity is critical when robots need to adapt to different tasks.

CNC-machined tool changers and fixtures allow robots to swap between welding, drilling, or gripping tools without downtime.

Advantages:

a. Boosts flexibility and task efficiency

b. Enables easy maintenance and upgrades

c. Reduces cost per operation in multi-task environments

4. End Effectors (Hands, Grippers, Claws)

These are the “hands” of the robot—interacting with tools, parts, and people.

CNC machining helps create end effectors with the right balance of strength, dexterity, and material compatibility.

a. Metal grippers for assembly lines

b. Suction-based end effectors for delicate handling

c. Hybrid 3D-printed + CNC parts for weight optimization

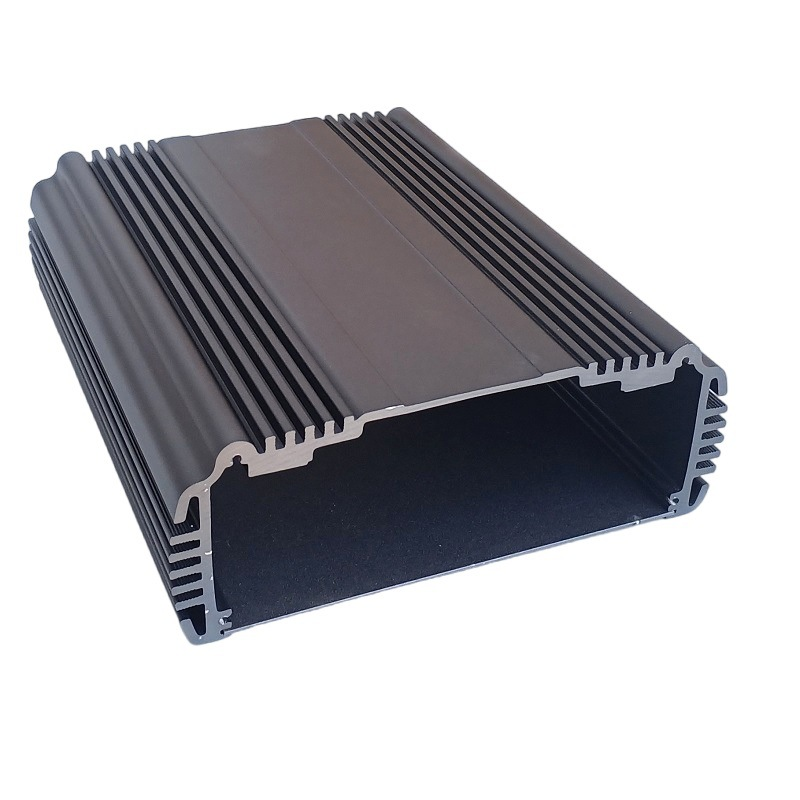

5. Motor Components (Rotors, Housings, Shafts)

Robotic motion requires controlled, consistent torque—delivered by finely machined motor components.

CNC ensures balanced rotors, durable housings, and optimized cooling pathways.

Why they matter:

a. Balancing rotors reduces vibration and extends lifespan

b. Durable housings protect motors from heat and impact

c. Integration with sensors allows real-time feedback

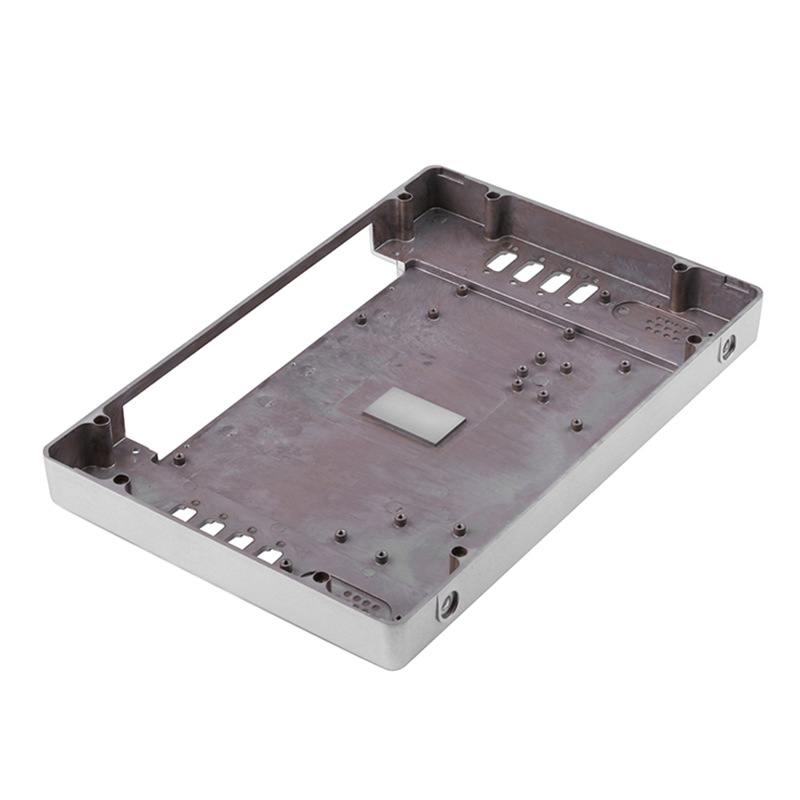

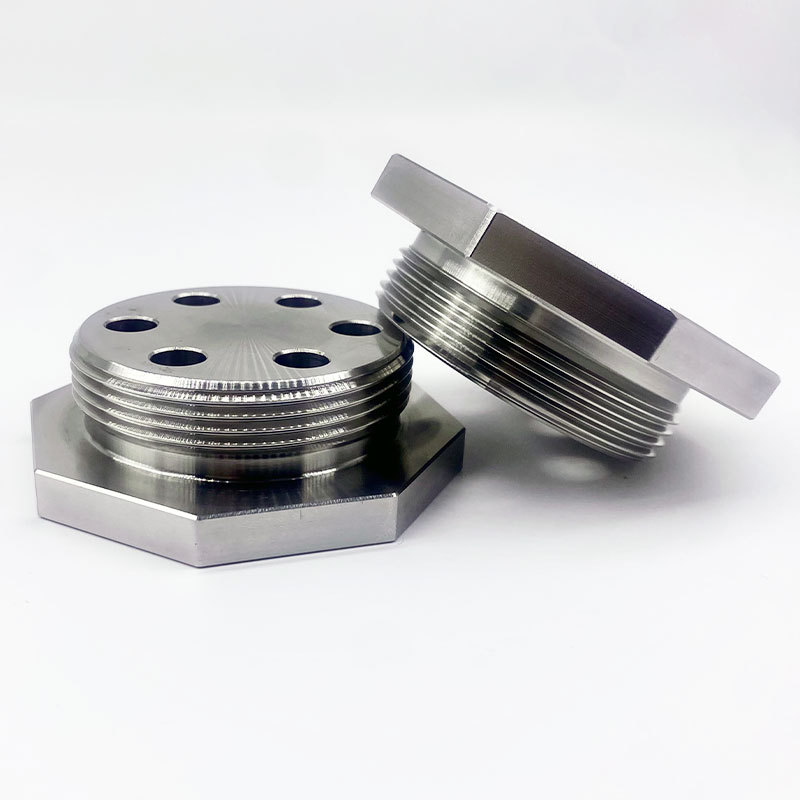

6. Assembly Fixtures and Positioning Trays

Even the smartest robots need guides.

CNC-machined trays and fixtures ensure robotic arms align and assemble parts with millimeter-perfect consistency.

Advantages:

a. Ensures perfect alignment in high-speed production lines.

b. Reduces assembly errors with automated positioning.

c. Essential for mass production in robotics and electronics.

How CNC Machines Shape the Future of Robotics?

CNC technology doesn’t just build robots—it empowers the future of intelligent manufacturing.

Here’s how CNC machines accelerate robotic innovation:

Micron-Level Tolerances – Allows precision that AI algorithms can depend on

Material Versatility – Machining works with aluminum, titanium, carbon fiber, polymers

Batch Repeatability – Enables high-volume production without deviation

CNC vs. 3D Printing in Robotic Parts

While 3D printing has revolutionized prototyping, CNC machining remains the king of functional robotic components. Why?

Feature | CNC Machining | 3D Printing |

Tolerance | ±0.001mm | ±0.05mm |

Material Strength | High (metals, carbon fiber) | Moderate (mostly plastics) |

Surface Finish | Excellent (polished or anodized) | Rougher, needs post-processing |

Scalability | Ideal for mass production | Limited due to slower print times |

What If You’re Sourcing CNC Robot Parts for the First Time?

If you’re a robotics startup, automation engineer, or procurement manager entering the CNC supply chain for the first time, here’s what you should know:

1. Choose your materials wisely – Aluminum is common for frames; titanium for high-strength applications.

2. Insist on tight tolerances – Especially for moving parts like gears and housings.

3. Request samples – Always evaluate finish, fit, and repeatability before large orders.

4. Ask about post-processing – Anodizing, polishing, or coating might be needed for durability.

5. Work with suppliers experienced in robotics – They’ll understand your performance demands better.

Pro Tip: Partner with CNC manufacturers who offer rapid prototyping as well as production scalability—it’ll save you both time and cost in the long run.

Conclusion

AI robots are only as strong, precise, and adaptable as the parts they’re built with—and that foundation comes from CNC machining.

As robots get smarter, smaller, and more capable, demand for precision parts will only grow.

Whether you’re designing AI systems, sourcing robotic components, or scaling up automation, understanding CNC parts is no longer optional—it’s essential.

Ready to optimize your robot builds? Start with the right CNC partner and the right parts. Precision today means performance tomorrow.