Precision metal shims are essential in many industries, ensuring accurate alignment, spacing, and tolerance adjustments in mechanical systems.

They are used across sectors like aerospace, automotive, and industrial manufacturing, where precision can mean the difference between success and failure.

But how exactly are these shims made?

Understanding the manufacturing processes helps you choose the right shim solution for your specific needs.

Precision metal shims are primarily manufactured using stamping, chemical etching, laser cutting, and CNC machining.

It is ideal for large-scale production, while chemical etching and laser cutting offer exceptional accuracy for intricate designs.

CNC machining, on the other hand, ensures customized solutions with tight tolerances.

By selecting the right method, manufacturers can produce shims that meet strict performance standards.

In this article, we’ll explore how each manufacturing process works, which materials are commonly used, and what technologies enhance the precision of metal shim production.

You’ll also discover how to select the right method for your industry.

-

Table Of Contents

-

1. How Are Precision Metal Shims Manufactured to Meet Your Industry’s Needs?

-

2. What Are Precision Metal Shims Made Of?

-

3. Manufacturing Process for Precision Metal Shims

-

4. How Are Laminated Shims Manufactured?

-

5. What Technologies Improve the Precision of Metal Shim Manufacturing?

-

6. How to Choose the Right Manufacturing Process for Your Industry?

-

7. Why Sustainability Matters in Shim Manufacturing?

-

8. What Are the Latest Trends in Shim Manufacturing?

-

9. Summary

What Are Precision Metal Shims Made Of?

Material selection is crucial when manufacturing precision metal shims.

The right material ensures the shim performs effectively under specific environmental and mechanical conditions.

Common choices include:

• Stainless Steel: Highly resistant to corrosion and wear, making it ideal for marine, industrial, and automotive applications.

• Aluminum: Lightweight and corrosion-resistant, often used in aerospace where reducing weight is essential.

• Brass and Bronze: Excellent electrical conductivity and corrosion resistance, suitable for electrical and instrumentation applications.

• Copper: Provides superior thermal and electrical conductivity, used in power generation and electronics.

• Specialty Alloys: For extreme environments, alloys with high-temperature resistance or enhanced mechanical strength are used.

Choosing the right material depends on the application’s demands, including environmental exposure, load-bearing requirements, and regulatory standards.

Manufacturing Process for Precision Metal Shims

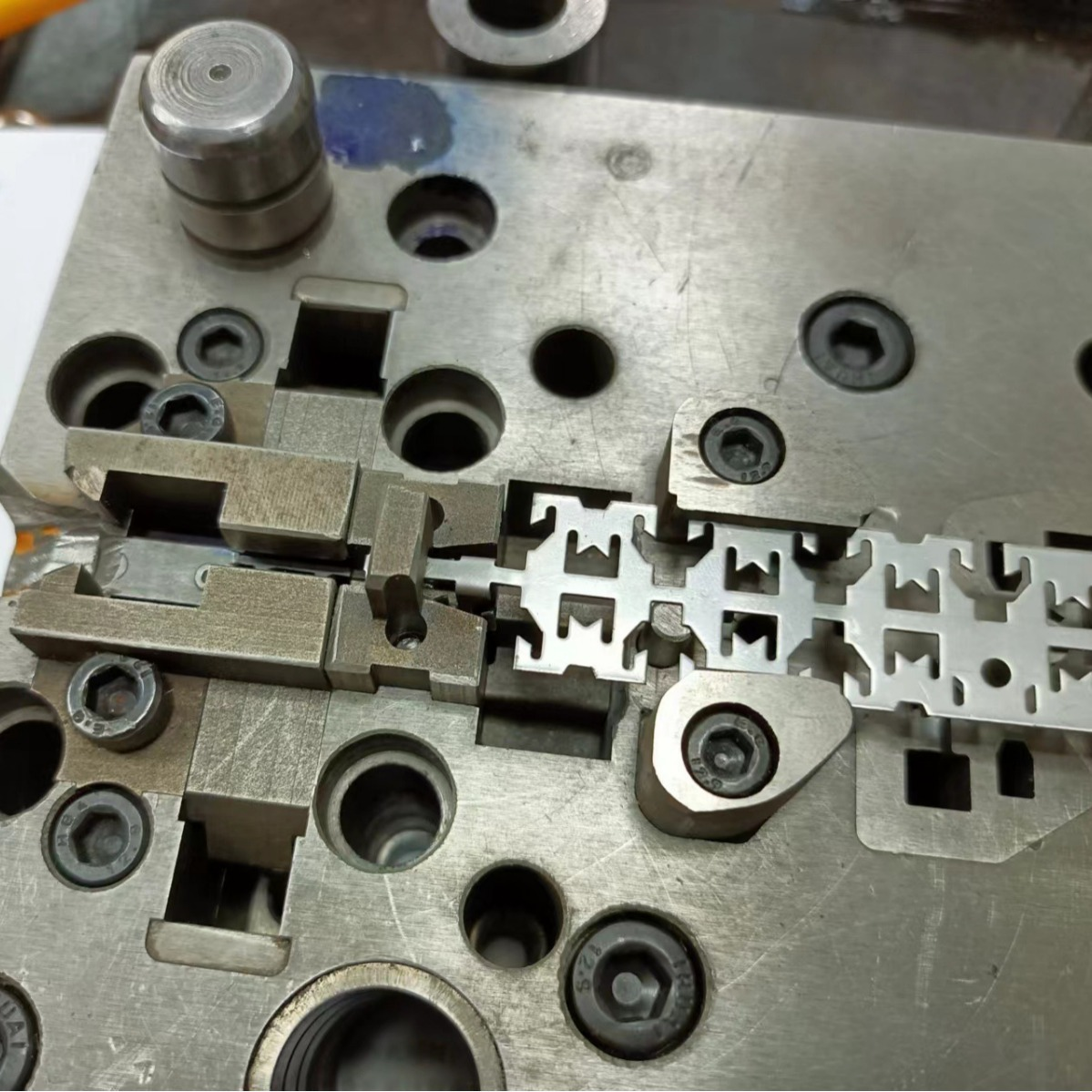

1. Stamping for High-Volume Production

Stamping is a fast and cost-effective method for producing large quantities of metal shims.

The process involves creating a custom die, pressing, and finishing, which punches and shapes the metal sheet with high precision.

Advantages:

• High production speed

• Consistent quality

• Low per-unit cost for large orders

Through our advanced metal stamping services, we can achieve exceptional accuracy while maintaining high production rates.

2. Chemical Etching for Intricate Designs

Chemical etching uses a photochemical process to remove material, creating complex patterns with extremely fine tolerances. It’s ideal for thin metal sheets and intricate designs.

Advantages:

• No mechanical stress on the material

• High design flexibility

• Suitable for prototype production and small batches

3. Laser Cutting for Precision and Flexibility

Laser cutting uses a concentrated laser beam to cut metal sheets with high accuracy.

It’s versatile and can handle various materials and thicknesses.

Advantages:

• Minimal material wastage

• Fast turnaround for custom designs

• High-quality edge finishes

4. CNC Machining for Custom Solutions

CNC (Computer Numerical Control) machining offers exceptional precision and flexibility.

Using computer-controlled tools, it creates customized shims with tight tolerances.

Advantages:

• Excellent dimensional accuracy

• Ideal for small production runs and prototypes

• Suitable for specialty materials

How Are Laminated Shims Manufactured?

Laminated shims are composed of thin metal layers bonded together, allowing for precise thickness adjustments.

Users can peel away layers to achieve the desired shim height without replacing the entire component.

Manufacturing Process:

1. Layering: Thin sheets are bonded with an adhesive.

2. Curing: Heat and pressure create a solid laminate.

3. Cutting: The laminate is shaped to the required dimensions.

Applications:

• Aircraft engine assembly

• Heavy machinery adjustments

• Industrial alignment tasks

Laminated shims provide flexibility and reduce downtime during maintenance, making them essential for industries requiring frequent adjustments.

What Technologies Improve the Precision of Metal Shim Manufacturing?

Technology plays a key role in enhancing the accuracy, efficiency, and sustainability of shim production.

The most impactful innovations include:

• CNC Machining: Ensures high repeatability and tight tolerances, especially for complex or custom designs. This method is ideal for prototypes and small to medium production runs requiring extreme accuracy.

• Waterjet Cutting: Uses high-pressure water to cut materials without heat, preventing thermal distortion.

• Digital Tooling: Reduces lead times and eliminates the need for physical dies in low-volume production.

• Quality Inspection Systems: Advanced sensors and vision systems ensure every shim meets strict specifications.

By adopting these technologies, manufacturers can deliver superior-quality products while minimizing material waste and production time.

How to Choose the Right Manufacturing Process for Your Industry?

Selecting the right process depends on factors like production volume, material type, design complexity, and required tolerances.

Here’s a quick guide to help you decide:

• High Volume, Simple Designs: Choose stamping for its cost-effectiveness.

• Complex, Thin Designs: Opt for chemical etching for intricate patterns.

• Custom, Small Batches: Use laser cutting or CNC machining for flexibility and precision.

• Adjustable Thickness Needs: Consider laminated shims for easy on-site adjustments.

Consulting with a manufacturer experienced in various processes will help you determine the most cost-effective and efficient solution.

Why Sustainability Matters in Shim Manufacturing?

With growing environmental concerns, manufacturers are adopting greener production methods.

Some sustainable practices include:

• Recycling: Using recycled metals to reduce waste.

• Energy-Efficient Technologies: Implementing energy-saving machinery.

• Waste Reduction: Utilizing nesting software to minimize material scrap.

By choosing manufacturers with sustainable practices, you contribute to a greener future while ensuring top-quality products.

What Are the Latest Trends in Shim Manufacturing?

The industry is rapidly evolving, with advancements shaping the future of precision shim manufacturing:

• Automation and AI: Robotics and AI algorithms are streamlining production and improving quality control.

• Additive Manufacturing: 3D printing is emerging as a method for producing custom and prototype shims.

• Material Innovation: The development of lightweight, high-strength alloys is expanding shim applications.

• Smart Manufacturing: Real-time monitoring systems optimize production processes and reduce downtime.

Staying informed about these trends can help you leverage the latest technologies for your manufacturing needs.

Conclusion

Precision metal shims are manufactured using a variety of processes like stamping, chemical etching, laser cutting, and CNC machining.

By understanding the strengths of each method, you can select the most suitable approach for your specific application.

Whether it’s achieving mass production efficiency with stamping or ensuring intricate accuracy with chemical etching, the right choice ensures reliability and performance.

Explore your options with experienced manufacturers to find the perfect shim solution tailored to your industry’s demands.