What is PVC Machining?

Polyvinyl chloride (PVC) is an incredibly versatile material prized for its durability, cost-effectiveness, and ease of machining.

It has become a go-to choice in various industries, from construction to electrical applications.

This comprehensive guide aims to demystify the intricacies of PVC machining, offering valuable insights into the types of PVC available, essential tools, best practices, and crucial safety guidelines.

Whether you’re an experienced professional or an enthusiastic hobbyist, mastering the art of PVC machining can significantly enhance your projects and yield superior results.

-

Table Of Contents

-

1. What is PVC Machining?

-

2. How Machinable is PVC?

-

3. Types of PVC Used in Machining

-

4. What Are the Best Tools and Equipment for Machining PVC?

-

5. What Speed Do You Need to Mill Plastic?

-

6. What Are the Safety Tips for Machining PVC?

-

7. Innovative Applications of PVC Machining

-

8. Summary

How Machinable is PVC?

PVC is renowned for its exceptional machinability, making it a staple in many manufacturing processes.

Its impressive mechanical properties offer a balance of strength and flexibility, which is essential for producing components that withstand various environmental stresses.

PVC exhibits excellent resistance to corrosion, flame, and water, making it ideal for applications that require durability and longevity.

When machining PVC, choosing the right cutting speeds and tools is vital for achieving precision and efficiency.

For example, if you’re using CNC machines or manual tools, applying the appropriate techniques will ensure high-quality parts with tight tolerances.

Moreover, understanding the thermal properties of PVC is essential; excessive heat can cause melting or warping, so managing cutting speeds is critical.

Types of PVC Used in Machining

PVC comes in several variations, each suited for different applications. Knowing the right type for your project can maximize productivity and ensure optimal results:

1. Rigid PVC (uPVC): This is the most commonly used type of PVC, known for its mechanical strength and rigidity.

It’s often used in pipe fittings, window frames, and sheet products. Its resistance to chemical corrosion makes it ideal for industrial applications where durability is paramount.

2. Flexible PVC: Unlike rigid PVC, this variant contains added plasticizers, which give it flexibility and softness.

It is commonly used in hoses, wire insulation, and soft tubing. Machining flexible PVC can be more challenging due to its properties, but it is achievable with the right tools and techniques.

3. Chlorinated PVC (CPVC): CPVC has added chlorine content, making it more resistant to higher temperatures and chemicals.

It’s commonly used in hot water pipes and chemical processing applications. While CPVC is just as machinable as rigid PVC, it requires slightly more precision to avoid chipping during machining.

What Are the Best Tools and Equipment for Machining PVC?

The tools and equipment used for machining PVC differ significantly from those used for metals or woods. Here are some commonly utilized tools and equipment:

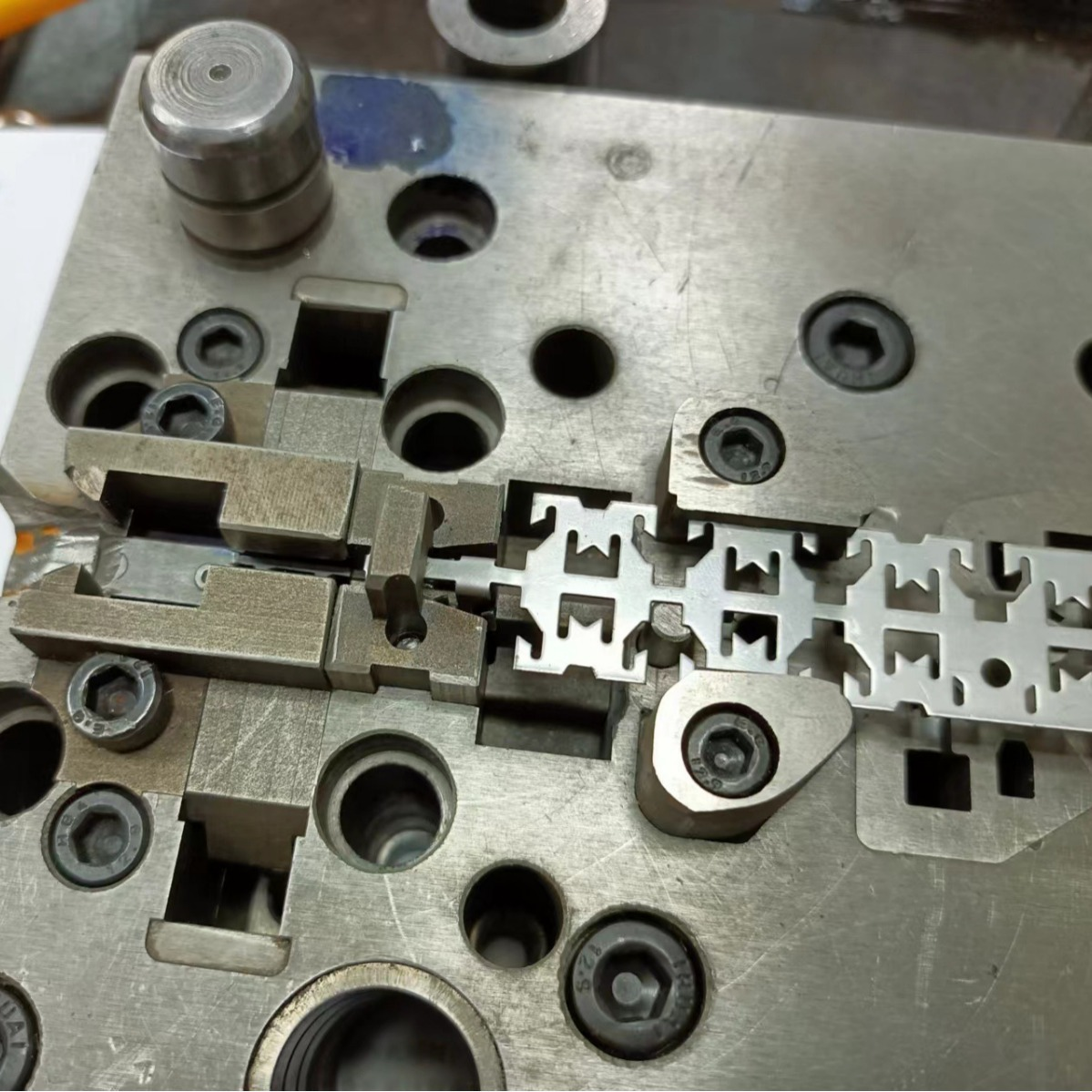

1. CNC Machines: Computer Numerical Control (CNC) machines are ideal for PVC machining due to their precision and capability to handle complex shapes.

The ability to adjust speed, feed, and depth of cut ensures clean cuts without excessive heat generation.

2. Carbide Cutting Tools: Using carbide-tipped cutting tools is essential as they can withstand the friction and heat produced during machining.

High-speed steel (HSS) tools can work as well, but carbide tools tend to offer better long-term results.

3. End Mills and Routers: For milling or routing applications, end mills designed specifically for plastics provide clean cuts without melting or deforming the material.

A low feed rate and moderate speed are recommended for achieving precision cuts.

4. Coolant Systems: Since heat generation is a concern when machining PVC, utilizing coolant systems—especially in high-speed CNC applications—helps to reduce friction and prevent material warping, thereby maintaining the integrity of the workpiece.

What Speed Do You Need to Mill Plastic?

One of the most critical aspects of machining PVC is determining the correct cutting speed.

Too much heat can lead to melting, while too little speed can result in poor finishes.

The ideal cutting speed for PVC typically ranges from 920 to 1640 feet per minute, depending on the specific type of PVC being used.

It’s advisable to start at the lower end of the speed range and gradually increase the speed if the material allows.

Monitoring the temperature of the material during machining is also crucial to prevent overheating and subsequent deformation.

What Are the Safety Tips for Machining PVC?

While machining PVC is generally safe, specific precautions should be taken to ensure a safe working environment:

1. Ventilation: Always ensure that the work area is well-ventilated. Machining PVC at high temperatures can emit harmful fumes, including hydrochloric acid gas, irritating the respiratory system.

2. Avoid Overheating: Managing heat generation is critical; excessive heat can cause the material to melt or burn, releasing toxic fumes.

3. Personal Protective Equipment (PPE): It is crucial to wear appropriate PPE, including safety glasses, masks, and gloves. Safety glasses protect against small plastic particles, while masks prevent inhalation of harmful fumes. Gloves help to avoid cuts or burns during machining.

4. Machine Maintenance: Regular maintenance of tools and machines is essential to ensure they remain sharp and properly calibrated. Dull blades or improper settings can lead to poor finishes and safety hazards.

Innovative Applications of PVC Machining

In recent years, PVC machining has opened new doors for creativity in various fields.

For instance, designers and engineers are exploring PVC’s potential in creating lightweight, durable prototypes for automotive and aerospace applications.

Additionally, the flexibility of PVC enables the production of intricate designs for decorative items, furniture, and even art installations.

Emphasizing sustainability, some manufacturers are now focusing on recycling scrap PVC, which reduces waste and lowers costs.

Companies can contribute to environmental conservation by machining recycled PVC while maintaining high-quality production standards.

Conclusion

PVC is a highly versatile and machinable material that is widely used for manufacturing quality parts across various industries.

By following the best practices outlined in this guide and utilizing the right tools and techniques, professionals and hobbyists can ensure safe, efficient, and accurate machining of PVC.

Always prioritize safety, keep your tools sharp, and maintain appropriate speed and feed rates for optimal results.

Embrace the innovative applications of PVC machining to push the boundaries of what is possible in your projects!