Stainless steel has become the go-to material for machine parts in countless industries, from aerospace to food processing.

Its unmatched durability, corrosion resistance, and adaptability make it a favorite among engineers and manufacturers alike.

But what exactly makes stainless steel so special?

Compared to materials like carbon steel or aluminum, stainless steel delivers a combination of performance and longevity that’s hard to beat.

It handles stress, heat, and chemicals without breaking down—making it ideal for high-demand environments.

Now, let’s explore how stainless steel compares to other metals, what benefits it brings to mechanical design, and why it may be the best investment for your next project.

-

Table Of Contents

-

1. Why Is Stainless Steel the Top Choice for Machine Parts?

-

2. What Makes Stainless Steel Outperform Other Metals?

-

3. How Does Stainless Steel Improve Machine Part Performance?

-

4. How Does Stainless Steel Reduce Maintenance and Downtime?

-

5. Which Stainless Steel Grades Work Best for Machining?

-

6. Isn’t Stainless Steel Harder to Machine?

-

7. Is Stainless Steel a Sustainable and Smart Long-Term Choice?

-

8. Summary

What Makes Stainless Steel Outperform Other Metals?

When selecting materials for machine parts, buyers and engineers face critical trade-offs.

Strength, cost, machinability, and environmental conditions all matter.

So, how does stainless steel measure up?

Corrosion Resistance Sets It Apart

Unlike carbon steel, which rusts without protective coatings, stainless steel forms a self-repairing chromium oxide layer.

This “passive film” shields the material from moisture, acids, and industrial chemicals—even after surface damage.

This means fewer part replacements, less downtime, and lower maintenance costs in the long run.

Superior Strength with Thermal Stability

Stainless steel delivers high tensile strength and doesn’t easily deform under load or vibration.

It also maintains its integrity at elevated temperatures, outperforming aluminum and carbon steel in heat-intensive environments like engines, turbines, or processing lines.

Versus Aluminum and Carbon Steel

Property | Stainless Steel | Aluminum | Carbon Steel |

Corrosion Resistance | Excellent | Moderate | Poor |

Strength | High | Lower | High |

Weight | Moderate | Light | Heavy |

Machinability | Moderate–Good | Excellent | Good |

Cost | Moderate–High | Moderate | Low |

Recyclability | Excellent | Excellent | Good |

While aluminum wins on weight, it can’t match the strength and wear resistance of stainless steel.

Carbon steel is cheap but comes with higher maintenance and lower corrosion resistance.

Stainless steel strikes a balance—robust, versatile, and resilient.

How Does Stainless Steel Improve Machine Part Performance?

Choosing stainless steel isn’t just about durability—it’s about enhancing overall machine performance, part precision, and user experience.

Mechanical Reliability

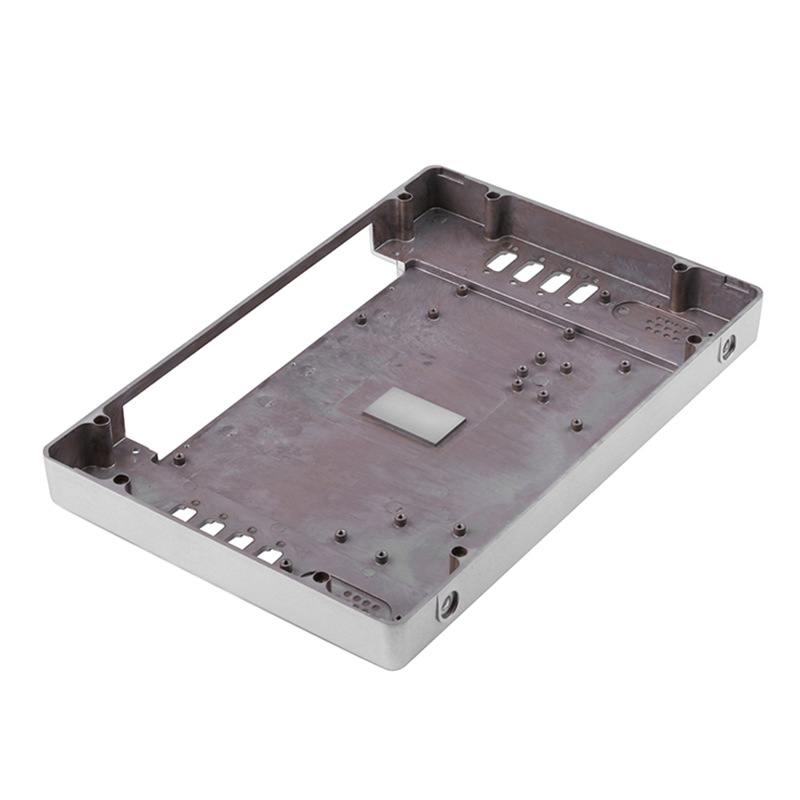

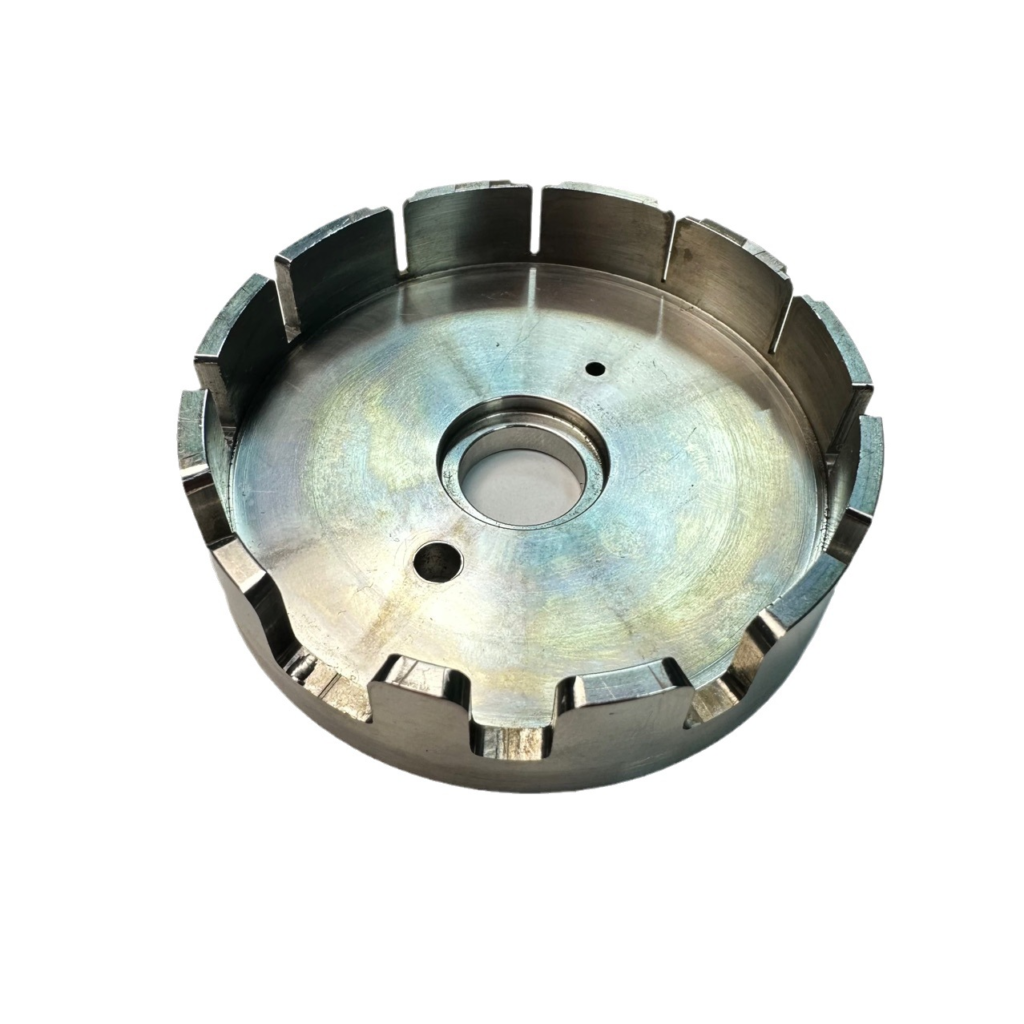

Stainless steel’s uniform mechanical properties reduce the risk of part failure under fatigue, torsion, or load.

It doesn’t warp easily during fabrication, which ensures high dimensional accuracy for components like shafts, gears, and housings.

Stable Under Pressure and Heat

In high-temperature environments, many metals weaken.

Stainless steel resists creep and deformation even when exposed to intense heat.

This is vital in automotive exhaust systems, chemical reactors, and turbine assemblies.

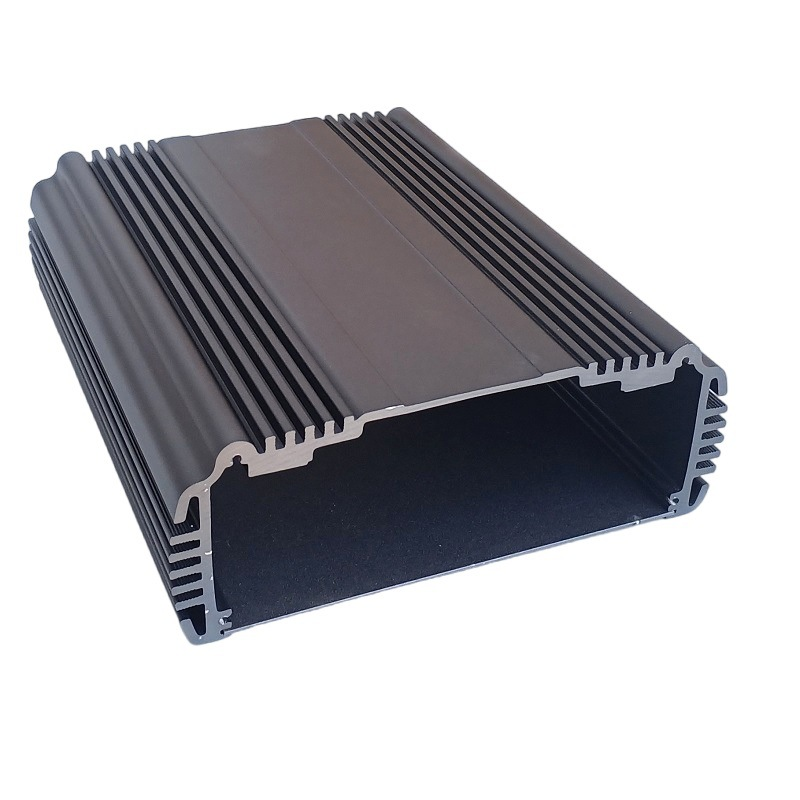

Low-Friction, High-Strength Design Options

Designers can reduce part bulk while maintaining strength thanks to stainless steel’s high strength-to-weight ratio.

Ribs and hollow sections help reinforce parts without unnecessary material—lowering both weight and material costs.

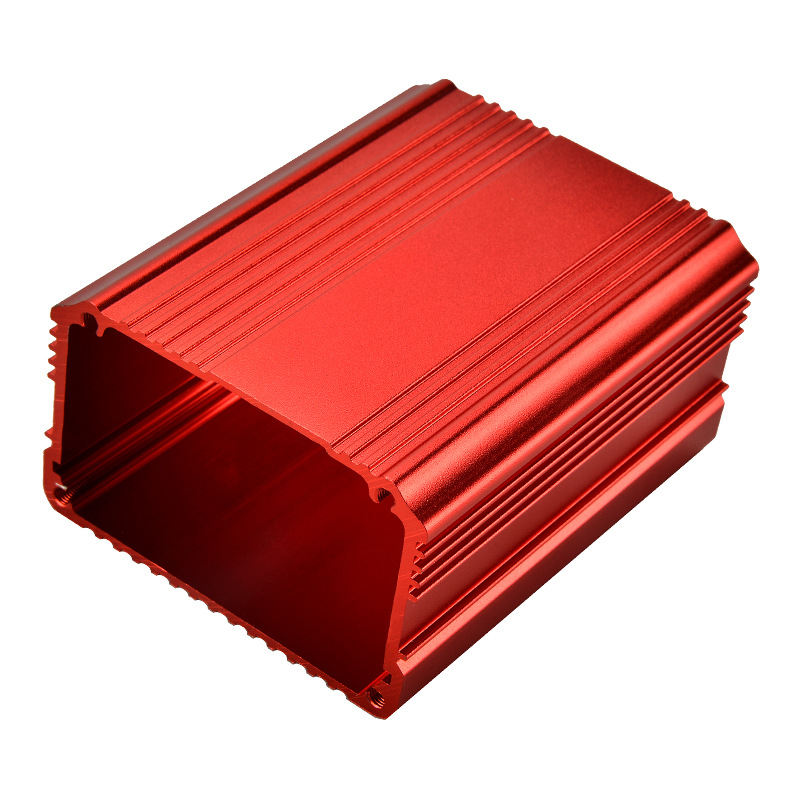

Aesthetic and Hygienic Appeal

Smooth, cleanable, and corrosion-free, stainless steel is ideal for visible parts or sterile environments. That’s why it dominates in food processing equipment, medical instruments, and commercial kitchens.

How Does Stainless Steel Reduce Maintenance and Downtime?

For procurement managers and factory operators, downtime equals money lost.

That’s why the material choice for machine parts must prioritize longevity and reliability.

Rust-Free Longevity

Stainless steel outlasts most alternatives in aggressive settings—like marine equipment, chemical handling systems, and outdoor machinery.

Unlike carbon steel, which may need recoating or replacement after corrosion damage, stainless steel keeps performing without extra protection.

Fewer Failures Mean Fewer Headaches

Cracking, warping, and galling are common in poorly selected materials.

Stainless steel, particularly in grades like 316 and 416, offers excellent resistance to wear, thermal fatigue, and stress-induced cracking.

The result? Fewer breakdowns, fewer repairs, and longer intervals between part replacements.

Lower Lifetime Cost Despite Higher Unit Price

Yes, stainless steel costs more per kilogram than carbon steel—but factor in maintenance, longevity, and reduced replacements, and it often wins on total cost of ownership.

Which Stainless Steel Grades Work Best for Machining?

Not all stainless steel is created equal. Choosing the right grade ensures optimal performance and ease of manufacturing.

• 303 – Great for fast, high-volume machining. Contains sulfur for enhanced machinability.

• 304 – The most common grade, offering a strong balance of corrosion resistance and formability.

• 316 – Superior corrosion resistance, especially against chlorides and chemicals; ideal for marine and chemical plant use.

• 416 – High machinability and wear resistance; used in shafts and gears.

• 400 Series (e.g., 410, 430) – Harder, magnetizable types with good strength and moderate corrosion resistance.

Each grade supports different needs. Work with your supplier or engineer to match the right one to your use case.

Isn’t Stainless Steel Harder to Machine?

It’s true—machining stainless steel isn’t as easy as working with aluminum.

It tends to work-harden, meaning it becomes tougher the more you machine it.

But with the right approach, it’s very manageable.

Best Practices for Machining Stainless Steel

• Use sharp, coated carbide or high-speed steel tools

• Maintain moderate feed rates and lower cutting speeds

• Apply plenty of coolant to reduce heat buildup

• Choose free-machining grades like 303 when speed is essential

The added effort pays off. You get strong, long-lasting parts that don’t corrode or deform—and fewer surprises down the road.

Is Stainless Steel a Sustainable and Smart Long-Term Choice?

Sustainability and lifecycle costs are becoming major concerns for today’s manufacturers.

Stainless steel shines in both areas.

100% Recyclable, 60% Recycled Content

Most stainless steel comes from recycled scrap. At end-of-life, your parts can be fully recycled without losing material properties. This makes it an environmentally and economically sound choice.

Outlasts the Competition

Its long service life often offsets the higher upfront cost. For critical components, fewer failures and reduced downtime can mean massive savings over time—especially in high-volume production or 24/7 operations.

Conclusion

If you need machine parts that last longer, resist corrosion, handle heat, and reduce maintenance headaches, stainless steel is hard to beat.

From design flexibility to lifecycle efficiency, its advantages touch every stage of production and use.

Before choosing the cheapest material, consider what you’re really buying: performance, reliability, and peace of mind. Stainless steel offers all three.