Many lighting projects face a frustrating dilemma: how to ensure both high performance and elegant design?

Standard LED strip setups often fall short—they overheat, look unfinished, or create patchy lighting that ruins the overall effect.

For architects, interior designers, and industrial engineers alike, finding a clean and durable way to mount and cool LEDs is essential.

Custom LED aluminum extrusions solve this issue by offering tailored housing that enhances heat dissipation, improves light diffusion, and supports the overall aesthetic.

They’re a smart upgrade that not only protects your investment but also transforms your lighting from functional to fantastic.

In this guide, we’ll explore how these custom profiles work, what types are available, how to choose the right one, and where to source them—giving you everything you need to make the right decision for your project.

-

Table Of Contents

-

1. Are Custom LED Aluminum Extrusions the Secret to Smarter, Sleeker Lighting?

-

2. What Are Custom LED Aluminum Extrusions and Why Should You Use Them?

-

3. Top Benefits of Using Custom LED Aluminum Extrusions

-

4. Key Types of LED Aluminum Extrusions and Their Uses

-

5. Custom vs. Standard: Why Go the Extra Mile?

-

6. Common Applications of Custom LED Aluminum Extrusions

-

7. How to Choose the Right Custom LED Aluminum Extrusion?

-

8. What Do Buyers Need to Know Before Placing an Order?

-

9. How Can Custom LED Extrusions Solve Installation Challenges?

-

10. Summary

What Are Custom LED Aluminum Extrusions and Why Should You Use Them?

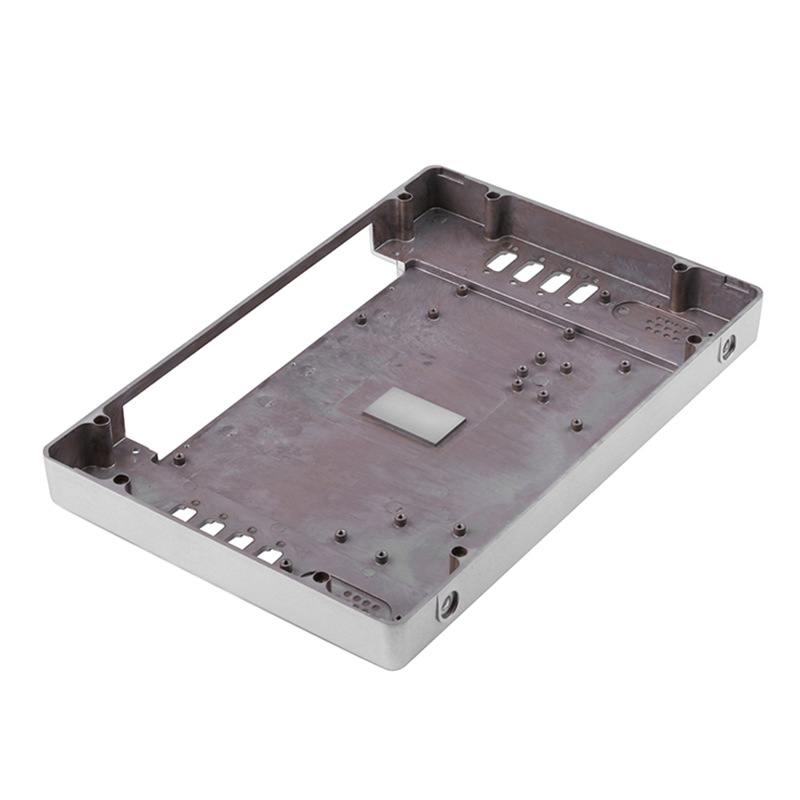

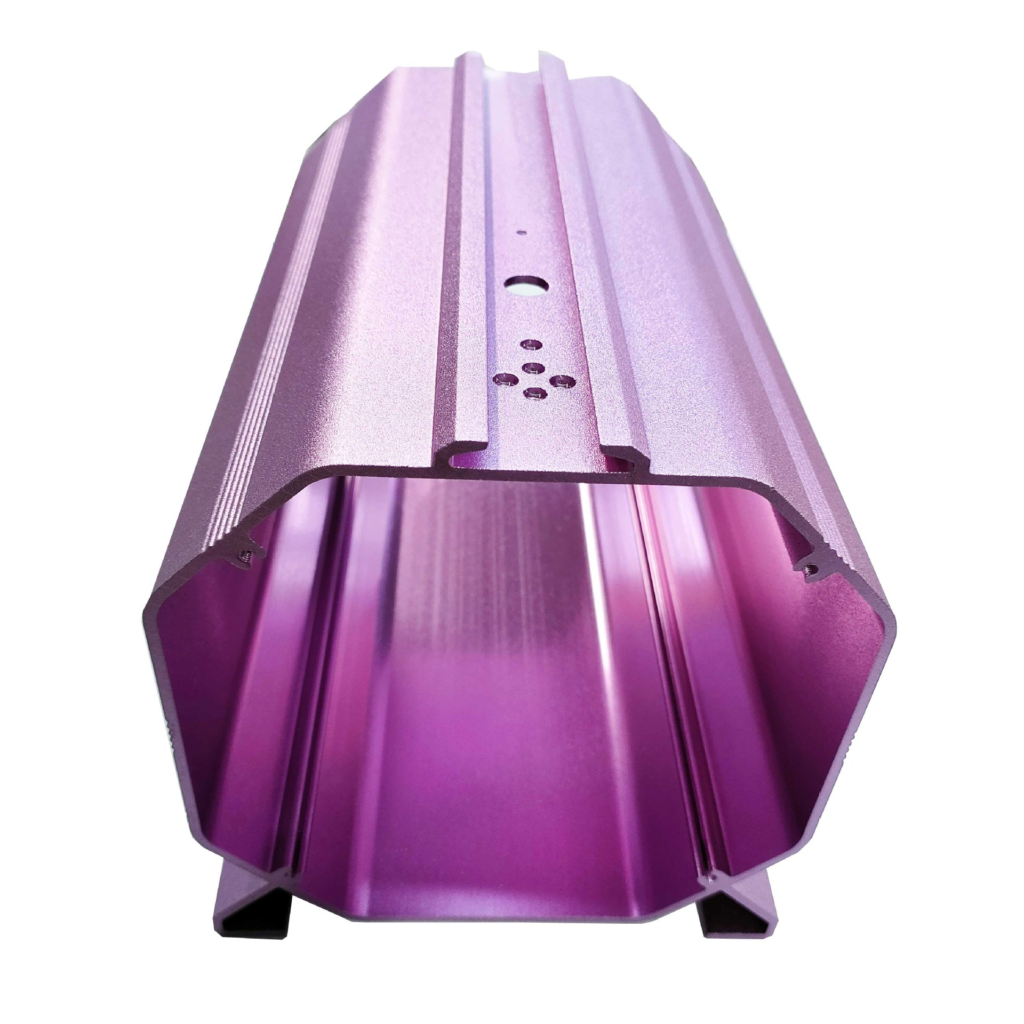

Custom LED aluminum extrusions are specially designed housings for LED strip lights.

Made from anodized or coated aluminum, they protect LED strips, serve as heat sinks, and provide a finished appearance for installations.

They also enable even light distribution when used with compatible diffusers—essential for spaces where visual consistency and comfort are key.

Unlike off-the-shelf profiles, custom extrusions are tailored to meet exact dimensions, finishes, and design needs.

Whether you’re working on a high-end kitchen, a luxury hotel, or a factory floor, these components give you control over both form and function.

Top Benefits of Using Custom LED Aluminum Extrusions

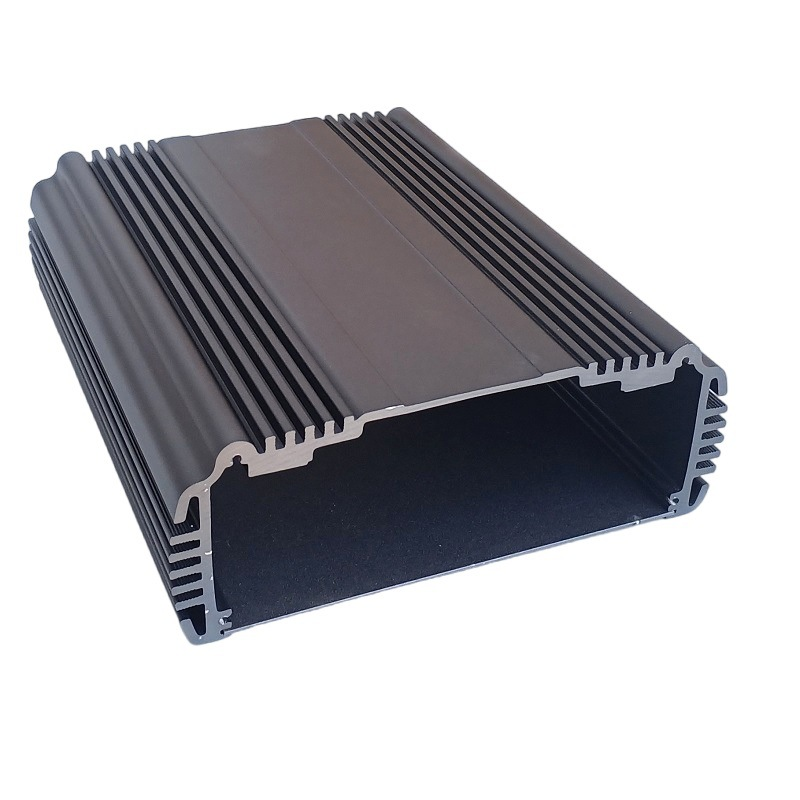

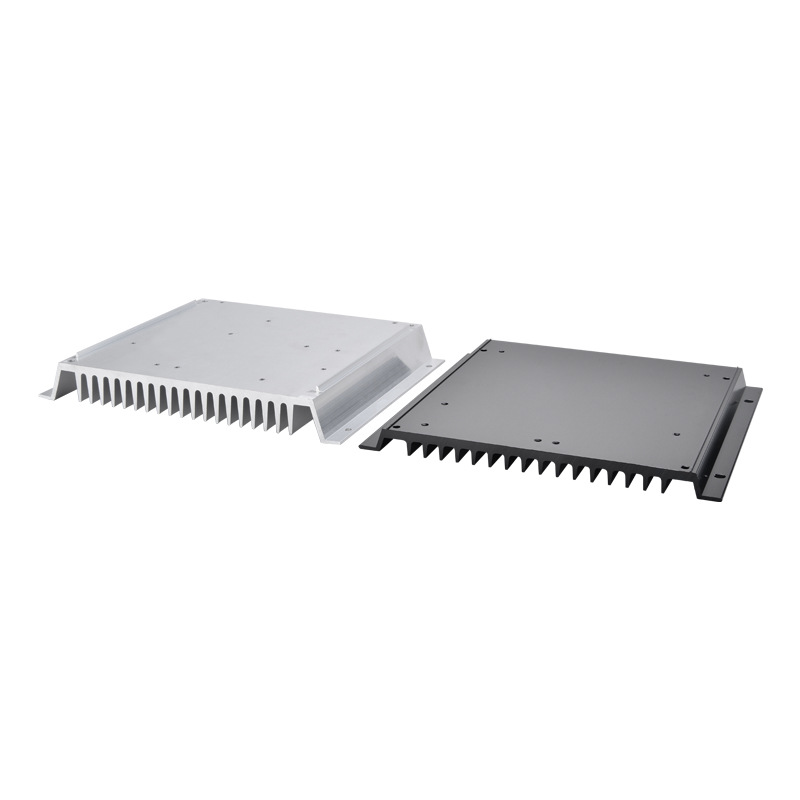

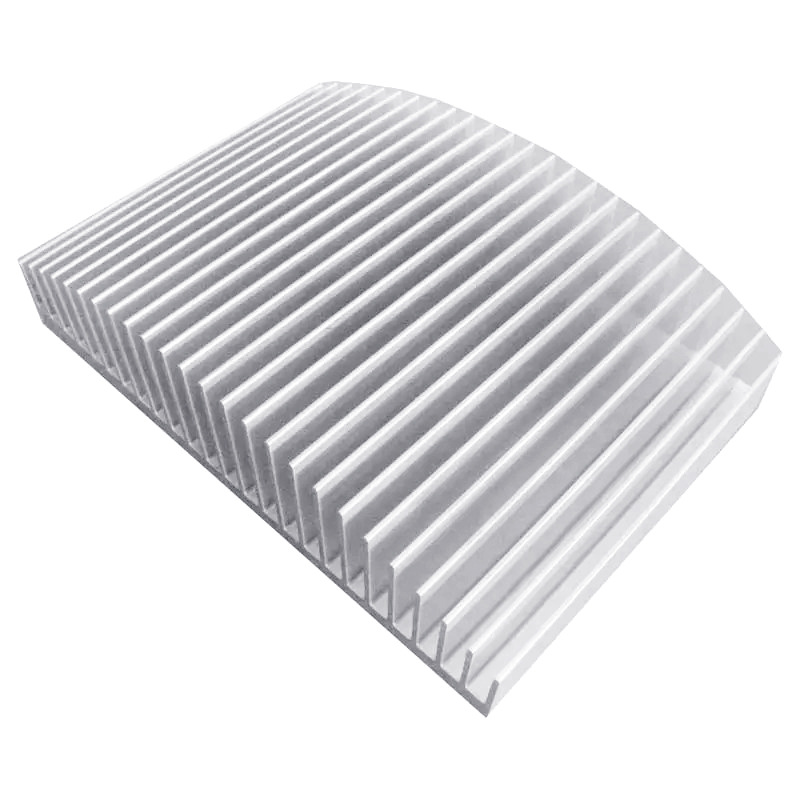

1. Effective Heat Dissipation = Longer LED Life

Heat is the enemy of LED performance.

Custom aluminum extrusions help dissipate heat effectively, preventing LED failure and ensuring longevity.

For commercial and industrial users, this means reduced maintenance and fewer replacements.

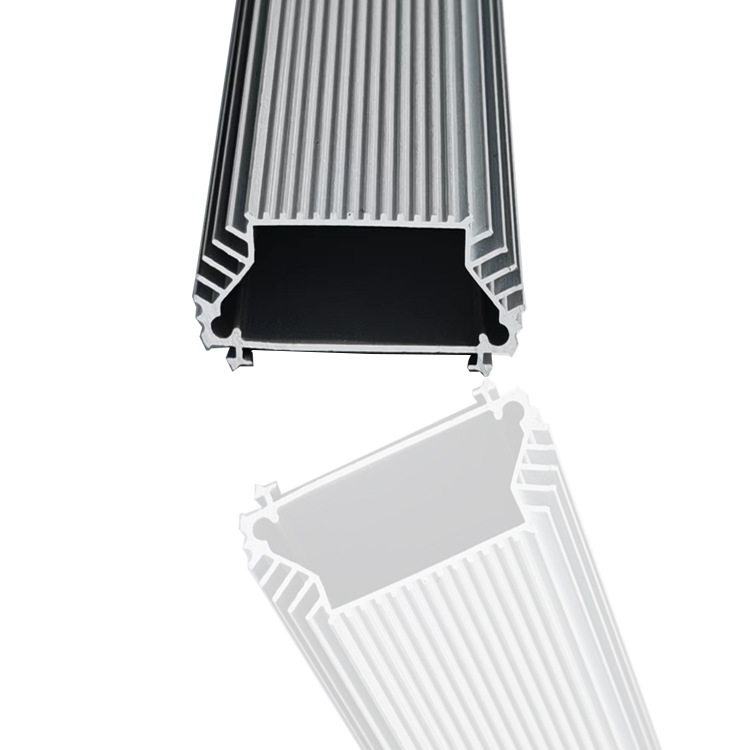

2. Even Light Distribution with No Hotspots

Pairing extrusions with diffusers eliminates glare and achieves uniform light output.

This is crucial in offices, hospitality settings, and home environments where lighting comfort matters.

3. Sleek Appearance and Superior Protection

Custom extrusions offer a professional, finished look.

More importantly, they shield LED strips from dust, moisture, and impact—especially important in rugged or outdoor environments.

4. Tailored Fit for Any Application

Have a unique corner, curve, or branding need?

Custom profiles adapt to non-standard spaces and offer unique finishes or branding options to match your project’s vision.

Key Types of LED Aluminum Extrusions and Their Uses

1. Surface-Mounted Profiles

• Best for: Under-cabinet lighting, workspaces, shelves.

• Advantages: Easy to install, visible, and stylish.

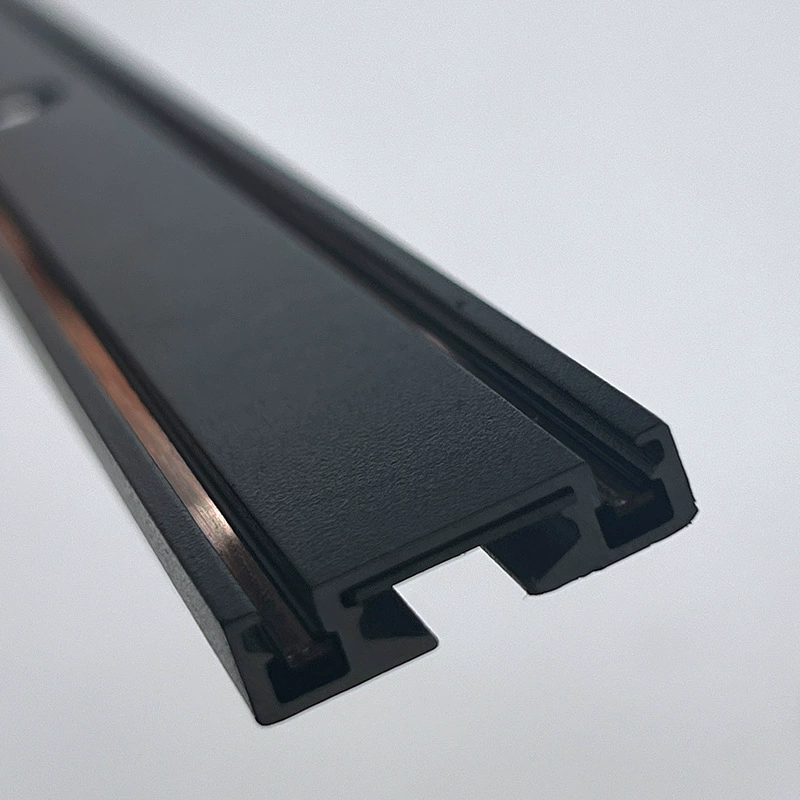

2. Recessed LED Channels

• Best for: Ceilings, walls, furniture.

• Advantages: Clean, flush finish with invisible mounting—perfect for modern interiors.

3. Corner LED Profiles

• Best for: Retail, stairs, display cases.

• Advantages: Optimizes angled installations and adds dramatic flair to displays.

4. Suspended LED Extrusions

• Best for: Offices, commercial halls, or industrial facilities.

• Advantages: Dual-purpose lighting—upward and downward—ideal for ambient and task lighting combined.

Custom vs. Standard: Why Go the Extra Mile?

1. Custom Means Precision

Standard profiles may force you to compromise on size or placement.

Custom extrusions eliminate these limitations by offering exact fits for unique configurations.

2. Enhanced Functionality

Choose specialized aluminum alloys, add waterproofing, or integrate smart control systems.

Custom profiles are more than holders—they’re part of the lighting system’s performance.

3. Better Brand Integration

Custom designs can incorporate logos, brand colors, or signature finishes.

This is ideal for retail stores, hotels, or architectural firms aiming for a cohesive brand image.

Common Applications of Custom LED Aluminum Extrusions

1. Architectural and Interior Design

Custom profiles elevate lighting in luxury homes, hotels, galleries, and office lobbies.

They support linear lighting trends and blend seamlessly into walls, floors, or ceilings.

2. Retail and Commercial Displays

Visual merchandising relies on strategic lighting.

Custom extrusions help focus attention on products while maintaining design consistency and reducing glare.

3. Industrial and Warehouse Lighting

In high-temperature, dusty, or vibration-prone environments, robust extrusions protect LED strips while meeting compliance standards.

4. Residential and Smart Homes

Kitchens, staircases, home cinemas, and bathrooms benefit from clean installations, dimming capabilities, and color-changing profiles for ambiance.

How to Choose the Right Custom LED Aluminum Extrusion?

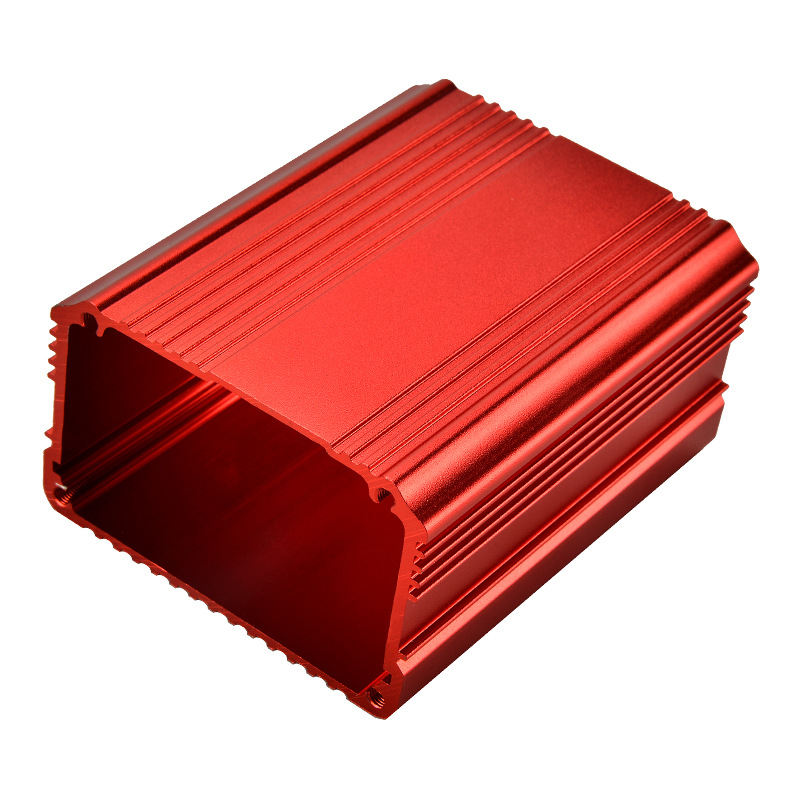

1. Material and Surface Finish

• Anodized Aluminum resists corrosion and looks sleek.

• Powder Coating allows for a broader color palette to match your interior design or brand identity.

2. Shape, Size, and Compatibility

Measure your LED strips (width and height) and choose a profile that allows for snug but breathable housing.

Flat, round, or angular shapes all serve different visual and structural purposes.

3. Diffuser Lens Options

• Clear: Maximum brightness.

• Frosted: Balanced light output with reduced glare.

• Opal: Uniform glow—ideal for decorative lighting.

4. Mounting Considerations

• Surface-mounting for simplicity.

• Recessed for minimalism.

• Suspended profiles for statement pieces.

• Waterproof models for outdoor or bathroom use.

What Do Buyers Need to Know Before Placing an Order?

Before selecting a supplier, ask:

• Can the extrusion be cut to specific lengths?

• Are mounting brackets or end caps included?

• Is there compatibility with your existing LED strips and power supplies?

• What’s the lead time for custom finishes or dimensions?

Also, confirm thermal performance ratings if your installation involves high-output LED strips.

How Can Custom LED Extrusions Solve Installation Challenges?

Custom extrusions aren’t just about looks—they’re problem-solvers. In real-world installations, lighting professionals face issues like uneven surfaces, limited space, or irregular mounting angles.

A well-designed custom extrusion can:

• Include adjustable brackets for angled ceilings.

• Integrate flexible joints for curved walls or stairwells.

• Offer snap-in or magnetic mounting for easier maintenance. For users looking to reduce labor time, avoid errors, and ensure long-term performance, choosing a custom extrusion means fewer surprises on the job site.

Conclusion:

Custom LED aluminum extrusions are more than a housing—they’re a strategic enhancement for lighting systems.

By improving heat management, light diffusion, and installation flexibility, they ensure that every lighting project meets performance goals and design expectations.

From retail to residential, from warehouses to wellness spas—wherever LED lighting goes, custom aluminum extrusions are the backbone that holds it all together.