Why Do Blisters Form in Aluminum Die Castings?

Blisters are a frustrating and costly defect in aluminum die casting, often compromising both the appearance and structural performance of parts. Whether you’re producing enclosures, housings, or load-bearing components, understanding what causes blisters is essential to avoiding downstream failures. Blisters typically form when trapped gases—such as hydrogen or air—expand beneath the surface during solidification or […]

What Defects Arise from Improper Wall Thickness in Die Casting?

Wall thickness plays a vital role in die casting design and production. Whether you’re making automotive housings, electronic enclosures, or industrial components, even slight inconsistencies in wall thickness can cause major issues. Many common casting defects—like porosity, warping, or incomplete fills—can be traced back to poorly managed wall geometry. So, what specific defects are caused […]

Why Is Uniform Wall Thickness So Crucial in Die Casting?

In die casting, uniform wall thickness isn’t just a design preference—it’s a fundamental requirement for quality, efficiency, and long-term performance. From cooling behavior to dimensional accuracy, wall uniformity influences nearly every aspect of part production and function. Ignoring this detail can lead to costly defects, inconsistent performance, and even product failure. So why exactly does […]

What Is the Minimum and Maximum Wall Thickness for Aluminium Die Casting?

Wall thickness is one of the most crucial design parameters in aluminium die casting. It directly affects part strength, cooling behavior, material usage, and overall production cost. Getting it right helps reduce defects, avoid unnecessary machining, and ensure the finished part performs as intended. So, what’s the ideal range? For most aluminium die cast parts, […]

Mold Design to Prevent Blisters in Die Casting

Blister formation is one of the most common surface defects in aluminum die casting, affecting both product quality and mechanical integrity. These defects appear as raised bubbles on the casting surface and can lead to functional failure, costly rework, or customer dissatisfaction. Mold design prevents blister formation by ensuring proper venting, smooth metal flow, balanced […]

How Can Ejector Pin Marks Be Prevented in Aluminum Die Casting?

Ejector pin marks are one of the most common surface defects in aluminum die casting, often affecting both the visual appeal and functional integrity of the finished product. These small circular indentations or blemishes, left behind when ejector pins push the solidified casting out of the mold, can compromise surface quality, increase the need for […]

Can Ejector Pin Marks Really Cause Structural Defects in Die Cast Parts?

In the world of aluminium die casting, surface quality is paramount. Among the most overlooked yet potentially serious imperfections are ejector pin marks—small circular impressions left behind when the casting is ejected from the mold. While often dismissed as cosmetic blemishes, could these marks actually lead to deeper structural problems? The short answer is yes. […]

Can Aluminium Die Cast Parts Have Varying Wall Thicknesses?

Aluminium die casting is a widely used process for producing complex, high-precision components. But can this process handle parts with varying wall thicknesses without sacrificing quality? This question is especially important for industries where lightweight designs and mechanical strength must go hand in hand. Aluminium die cast parts can feature varying wall thicknesses, but careful […]

How Can We Choose the Best Tools to Drill Through Cast Iron?

Drilling through cast iron can be a challenging task, requiring precision and the right tools to ensure a clean, accurate hole without damaging the material. Understanding the tools and techniques for this job is crucial. Use a cobalt drill bit for the best results when drilling through cast iron. These bits are highly heat-resistant, abrasive, […]

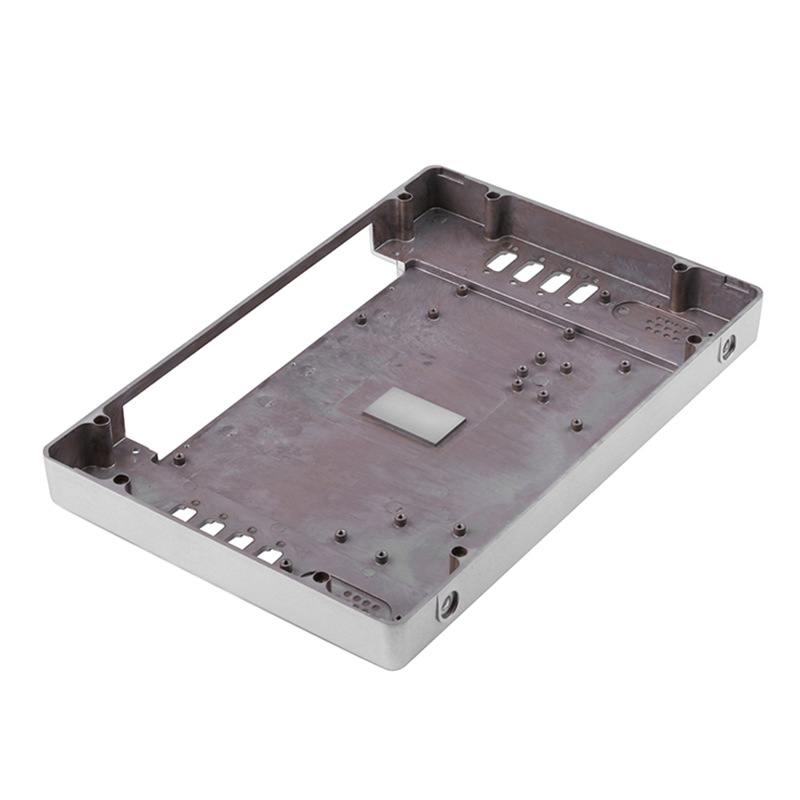

Understanding Die Casting: A Comprehensive Guide for Manufacturing Professionals

Die casting is a vital manufacturing process widely used to create complex metal parts with high precision. Understanding its intricacies can significantly benefit manufacturing professionals, engineers, and potential buyers looking to leverage this technology for their projects. Die casting is a high-pressure metal casting process that injects molten metal into a mold. This method yields […]